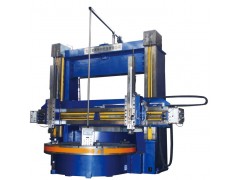

1. Such series of lathe are featured with high bearing capacity, reasonable price and excellent performance.

2. Large base, working platform, ring hear and guide plate pf working platform.

3. The working platform adopts the type of purely static pressure with bearing as high as 32 tons. (400 tons as the maximum)

4. Excellent casting (HT300) is handled by heat aging.

5. The beam which is widened 200 mm owns the strong stiffness and such possibility as ptosis can be never occurred.

6. The guide surface of beam is handled with hardening (HRC≥50), the vertical tool holder ram adopts ductile iron materials and treated with sticking plastic of sliding surface, which is duration is use and prolongs the repair cycle significantly.

7. Manual lubrication pump carries out oiling to different lubricating parts on a timing and quantitative basis.

8. High quality, high reliability of the electrical components, Japan Omron PLC control.

9. Independent hydraulic station facilitates adjustment, repair and maintenance.

10. Grating digital display device is equipped.

11. JB/T4116-96 precision test standard of vertical lathe is performed.

JB/3665-96 technical condition of vertical lathe is performed.

12. Complete processing and assembly process and strict quality control flow ensure the products reach perfect and first0class perfect quality.

13. High-precision speed-changing gear (Grade 6 precision) and high-precision gear grinding spiral bevel gear (Grade 6 precision) are featured with of low noise and stable operation.