RO Water treatment machine (2T/H) System Overview

This system adopts the most advanced Reverse Osmosis pure water filter technic. Its water production conductance rate generally less than 5us/cm, which precede the national standard GB17323-1998.The water made by this system is asepsis, non-granule and pure.

The RO membranes of this system adopt ESPA-4040 of American HYDRANAUTICS Its desalting rate can highly reach 98% and callback rate can be reach 50-75%, which are its special technical manner. Many pure water manufacturers had proved this whole set system that the remove rate of germina in water, poisonous heavy metal, radionuclide, organic micro pollution can highly reach 99.99%, 95%,

99% and 95%. After removing the poisonous and harmful substance in water basically, many toxicological index, such as organics, benzene, tetrachloride, pesticide, hydroxybenzene and plumbum, hydrargyrum, chrome, cadmium, uranium etc.

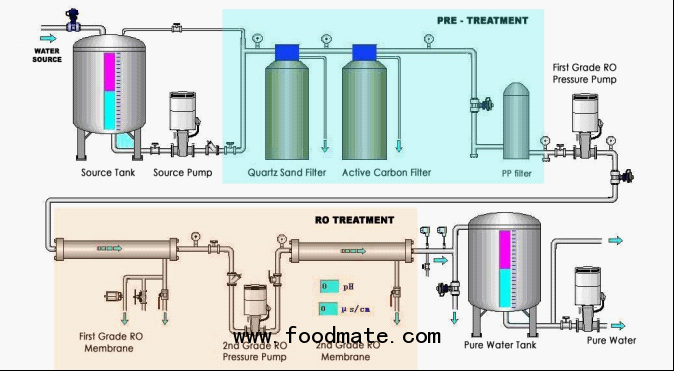

Pictures:

As shown on the attached filtration spectrum, our water treatment machine is composed of the following in basic for covering all the

filtration part according to the spectrum with different filter parts.

1. Silica sand filter

2. Active carbon filte

3. PP sediment micron filter

4. Reverse Osmosis membrane filteration

The first 3 parts we call it pre-treatment, and the pre-treatment part will be designed compatiable with the RO part according to specific water condition from the buyer, the following devices can be an optional choices to be added into the pre-treatment part for optional choice for customized water treatment purpose:

1. Resin water softener with automatic backwash control

2. Pulsafeeder brand PAC chemical dosing machine for anti-scalant chemical dosing, for Chloride removal, for PH ratio adjustment

3. PLC control system

Our water treatment system has single pass type and two grade type with "HYDRANAUTICS" brand RO membrane in basic, "FILMTEC" desalination RO membrane for optional choice according to customer's water condition, pure water output capacity we have machines ranging from 300L/H to 20,000L/H in basic, larger system will be upon customer request.

Technical scope:

|

Operating temperature |

15-40 C 25C can make the membrane on it's best situation, if the users' temp lower than 15C must add heating system. |

|

Electrical equipments |

standard 380V 60HZ other customer design for choose, but the cost for the electrical change need be confirmed and pay by buyer. |

|

Input water quality |

City tap water, Well water, River water etc. It's better that buyer send the local water quality report to seller, we will give suggestion for choising the machine or auxiliary machines. |

|

Product quality |

TDS<10us/cm Accord with national bottled water standard GB17323-1998(china), the final quality need confirming with the user's input water quality. |

Please check the attached PDF drawing of this machine ..

Technical parameter:

|

Singel grade machine 2T/H |

|||||

|

Name |

Meterial |

Made by |

Model |

Qty |

Remarks |

|

Feed pump |

Stainless steel 304 |

Nanfang pump co. China |

CHL4-220 |

1 |

Flux: 5T/H |

|

Quartz sand filter |

Stainless steel 304 |

Angel |

Ф500×1200×δ1.5 |

1 |

Quartz sand: 800kg |

|

Active carbon filter |

Stainless steel 304 |

Angel |

Ф500×1200×δ1.5 |

1 |

Active carbon: 300kg |

|

PP precise filter |

Stainless steel 304 |

Angel |

Ф250×1000×δ1.5 |

1 |

5u x 1000mm filter |

|

RO membrane |

TFC |

HYDRANAUTICS |

ESPA-4040 |

8 |

pressure 0.8-1mpa |

|

RO membrane housing |

Stainless steel 304 |

Angel |

4080 |

6 |

|

|

RO pressure pump |

Stainless steel 304 |

Nanfang pump co. China |

BLC4-075 |

1 |

4-6T/H |

|

Flow meter |

|

Suzhou China |

5T |

2 |

|

|

Solenoid Valve |

|

Shanghai China |

DF25 |

1 |

|

|

Main machine chassis |

Stainless steel 304 |

Angel |

3T type |

1 |

|

|

Ozone system |

|

BNP |

20g |

1 |

|

|

Storage tank |

Stainless steel 304 |

Angel |

2T: Ф1650 x 2340 |

1 |

|

|

Electronic component, pipe connection, pressure gauge etc; 2 set of start-up system, spare parts for 3 years operation manual(English), packing box |

|||||

|

Multi grade machine 2T/H |

|||||

|

Name |

Meterial |

Made by |

Model |

Qty |

Remarks |

|

Feed pump |

Stainless steel 304 |

Nanfang pump co. China |

CHL8-30 |

1 |

Flux: 8T/H |

|

Quartz sand filter |

Stainless steel 304 |

Angel |

Ф750×1500×δ3.0 |

1 |

Quartz sand: 800kg |

|

Active carbon filter |

Stainless steel 304 |

Angel |

Ф750×1500×δ3.0 |

1 |

Active carbon: 300kg |

|

PP precise filter |

Stainless steel 304 |

Angel |

Ф330×500×δ1.5 |

1 |

5u x 1000mm filter |

|

RO membrane |

TFC |

HYDRANAUTICS |

ESPA-4040 |

10 |

pressure 0.8-1mpa |

|

RO membrane housing |

Stainless steel 304 |

Angel |

40*120 |

8 |

|

|

1st RO pressure pump |

Stainless steel 304 |

Nanfang pump co. China |

CDL4-160 |

1 |

4-6T/H |

|

2nd RO pressure pump |

Stainless steel 304 |

Nanfang pump co. China |

CDL4-180 |

1 |

3-4T/H |

|

Flow meter |

|

Suzhou China |

5T |

3 |

|

|

Solenoid Valve |

|

Shanghai China |

DF25 |

1 |

|

|

Main machine chassis |

Stainless steel 304 |

Angel |

3T type |

1 |

|

|

Ozone system |

|

BNP |

20g |

1 |

|

|

Storage tank |

Stainless steel 304 |

Angel |

2T: Ф1650 x 2340 |

1 |

|

|

Electronic component, pipe connection, pressure gauge etc; 2 set of start-up system, spare parts for 3 years operation manual(English), packing box |

|||||

Note:

1. All the valves, flange, elbow, water related parts are made by Stainless Steel 304

2. The pump we have Denmark Grundfos for customer choice, the customer also can make designation of pump brand

3. For the RO membrane we have U.S. Filmtec membrane for choose, the customer also can make designation of pump brand

4. All the change of configure the seller will confirm the price with buyer

3.1 Disinfectant-adding device

Coagulation devices, add coagulating agent before the raw water enters into active carbon filter. This is uses to form the suspensions, colloids, micro particles etc into flocks large particles in order to got rid of them more easily by sand filter. The PH adjustment device can adjust the PH valve of raw water, making the inlet-water of RO optimization.

(you should show me your Raw water test report ,then we will know if you are in need the Disinfectant-adding device and PH adjustment device.)

3.2 Machine filters (the quartz sand filter.)

The raw water is purified simple by the filter. The filter mainly removes the suspend matter, colloid and other big impurity. If pressure dispersion of the water entering and water out exceeds 10Psi(0.7kg/cm2)or the water out SDI>5, the filter need to be back flushed. Commonly, the filter should be back flushed once before operation every day and also be back flushed with gas once a week.

3.3 The active carbon filter.

The active carbon is made of wood, coal, fruit shell (stone) and other carbonaceous material through the method of chemical activation or physical activation. It has a great deal of micro-holes and huge surface, so it has very strong physical adsorption capability to adsorb the organic infecting of the water. The filter mainly removes the organic substance, chlorine, odor, chromo and etc to make the left chlorine ≤0.1mg/l. So as protect the RO membrane from damage by the chlorine. The active carbon should be replaced every 12 to 15 months according to the content of the chlorine mostly. Commonly, the filter should be back flushed every week.

3.4 The RO device.

The RO device removes the hydronium, organic substance, colloid, bacteria and other impurity by the method of membrane. And the water can be desalted and purified. The theory is as follows. The treated water and the untreated water are separated by the membrane; the treated water osmoses to the untreated water. There is osmotic pressure between the two. If the pressure is added to the untreated water and the pressure of the untreated water is bigger than the osmotic pressure, the water of the untreated water osmoses to the opposite position of the water. This applies the reverse osmosis to the desalted water. That is to say the untreated water is purified into the pure water through the RO membrane under adequate pressure. The left water which can not osmosis through the membrane contains a lot of solute and suspended substance, and it will be drained out as waste water.

The RO device consists of 5µm precision filter, the first high-pressure pump, the second high-pressure pump, the middle tank, the pressure vessel,the RO membrane module, the pressure gauge, the flow meter, the conductivity meter and etc.

The water must be pretreated before entering into the RO system, or it will bring damage to the RO membrane. The RO system not only can be used for desalination, but also for filtering the organic substance and bacteria. The production of water is monitored by the liquid crystal display conductivity meter.

The RO system needs be cleaned timely, including the stainless steel pump, filter, disinfectant tank, valve and other components.

Commonly, the RO system should work once every day. If it does not work in one week, it must be protected by some measures, or the service life of the membrane will be serious affected.

3.5. Ozone mixing device

This system configuration 100g/h ozone device, necessary has the compressed air dryer, the oxygen generator, and the ozonizer to equal three. The compressed air enters the dryer to carry on the drying process first, then enters the oxygen generator system to take the oxygen, finally the oxygen enters the ozonizer system to take the ozone, what needs to pay attention is the ozonizer needs the cooling water to carry on cooling, the cooling water leakage may recycle in the original basin.

3.6 UV Disinfection Device

Principle : As the ultraviolet light energy is absorbed by the organisms, so it leads to the changes in the cell itself, especially the nucleic acid of the cells, when it absorbs much UV in the rage of 240-260nm, this causing the genetic factor change, function damage, lose reproductive capacity. The microorganisms which has lost reproductive capacity, when it irradiates by UV, the organisms occurs expansion, making the material outflows in vivo biological until it is necrosis, resulting in the death of bacteria. So that it plays the role of sterilization and preservation.

Shenzhen Angel Drinking water Equipment Co.,Ltd.

|

Name |

Quantity |

Price FOB China |

|

Single grade system stainless steel type |

||

|

Single grade Ro main machine |

1 set |

$7,400 |

|

Pure water tank |

1 set |

$320 |

|

Ozone generator and pump pipes 20g |

1 set |

$2,000 |

|

Pipes and valves for processing |

1 set |

free |

|

Seaworthy-standard wooden packing |

1 set |

free |

|

2 years standard spare parts |

1 set |

free |

|

|

Total |

$9,720 |

|

Multi grade system stainless steel type |

||

|

Multi grade Ro main machine |

1 set |

$9,570 |

|

Pure water tank |

1 set |

$320 |

|

Ozone generator and pump pipes 20g |

1 set |

$2,000 |

|

Pipes and valves for processing |

1 set |

free |

|

Seaworthy-standard wooden packing |

1 set |

free |

|

2 years standard spare parts |

1 set |

free |

|

|

Total |

$11,890 |

Remarks:

1. Delivery time:

Around 25 days after we confirm receive 30% down payment and clients’ requirement.

2. Payment term:

By TT, whereas 30% deposit should be made for confirming the order..

3. Guarantee:

One year quality guarantee and spare parts for one year free of charge.

4. Valid time:

From 21th Sep, 2012 to 21th Nov., 2012.

5. Others:

If the buyer requests seller to send engineers to go abroad to install equipments and training buyer’s engineers, the buyer should pay all cost of the seller’s engineers, such as go and back air tickets, local housing, food, transportation etc and allowance of USD60 per day.