Mineral water , natural water , spring water or energy drinking water making machine

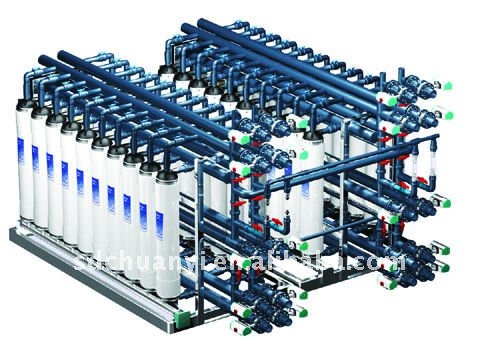

Ultra-filtration is a pressure driven membrane separation technology. The aim of the technology is to separate macromolecules and small molecules whose membrane pore size is between 20-1000A. Hollow Fiber Ultra-filter has the advantages of high density and compact structure.

In the ultra filtration process, the water depth is driven by hydraulic pressure and flows through the membrane surface. The ultra filtration process is a dynamic filtration,separation is accomplished in the mobilization state. Solute in the membrane surface is only a limited deposition, the ultra filtration rate to a certain degree of attenuation tends to balance, and can be restored by cleaning.

Specifications:

1. It's convenient to manage equipment: there needs only one main engine to generate water, that can supply numerous terminal for use at the same time, so purified water equipments can be managed in concentration.

2. Investment of equipments and operating cost reduces: when there are lots of terminal points, using central highly purified system will reduce investment of equipments and operating cost.

3. Remote full-auto control mode, fits for the requirements of modern lab building, combining techniques of PLC,touch screen,monitoring control, etc with remote control, can control water system equipments in graceful office far away from engine room via computer operation. However needs no special human operate it in engine room. and can

4. Using concentrated Water-generated engine, so there needs not to install water machine and water Box in Laboratory, this can save foot-print of equipments in laboratory, fit the decorating requirements of lab building.

Application:

It applied for drinking mineral water, spring water, industrial ultra-filtration water and pre-pretreatment of pure water facilities.