KQ/GD150 Lollipop Production line

Full-automatic,PLC control

Competitive price/services

Various shape/taste

*environmental protection

*CE approved & ISO standard

KQB150/300/400/600 lollipop depositing line is a compact unit which can continuously produce various kinds of candies under a strict sanitary condition. It is also ideal equipment which can produce out good quality products with the saving of both the manpower and the space occupied.

* PLC /computer process control available;

* An LED touch panel for easy operating;

* Optional (mass) flowing controlled by Frequency inverters ;

* In-line injection, dosing and pre-mixing techniques for the proportional addition of liquid(milk); Dosing pumps for the automatic injection of colors, flavors and acids

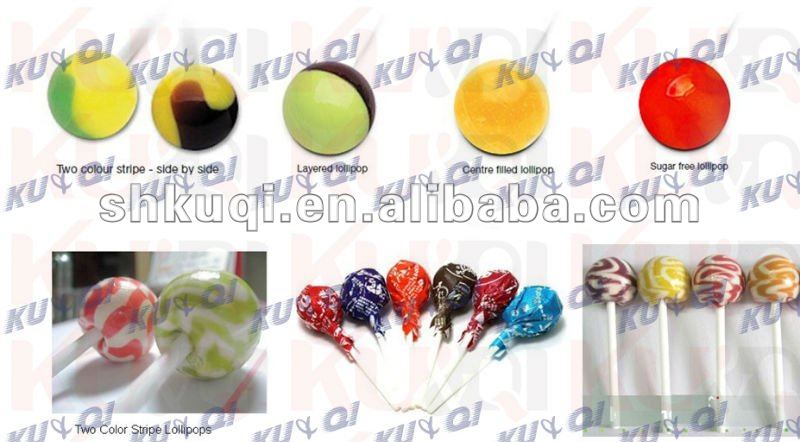

* One set of extra chocolate paste injection system for making chocolate-central candies; "two/three-color striped depositing”,” two /three–color double layers depositing", "central filling", "clear" hard candies, lollipop can be made.

* Moulds can be made according to the candies samples provided by the customer."

WORKING PROCESS:

Raw material dissolving→Conveying→Filting→Storaging→Constant Syrup converying→Pre-heating→Micro-film vacuum cooking→Mixing with

flavor and color→Depositing→Stick Inserting→ Cooling→De-moulding→ Conveying→Packing→Final products

|

MODEL |

KQ150 |

KQ300 |

KQ450 |

KQ600 |

|

Capacity(kg/hr) |

150(kg/hr) |

300(kg/hr) |

450(kg/hr) |

600(kg/hr) |

|

Max candy weight |

26g |

26g |

26g |

26g |

|

Lollipop Diameter |

Flat:18-28mm Ball:Max 25mm |

|||

|

Depositing speed |

55-65n/min |

55-65n/min |

55-65n/min |

55-65n/min |

|

Stick Specification |

60-100mm |

60-100mm |

60-100mm |

60-100mm |

|

Compressed air requirement |

0.2m³/min, |

0.2m³/min, |

0.2m³/min, |

0.2m³/min |

|

Working condition |

Temp:20-25°C |

Temp:20-25°C |

Temp:20-25°C |

Temp:20-25°C |

|

Total Power |

18kw/380V |

27kw/380V |

34kw/380V |

38kw/380V |

|

Total Length |

17m |

19m |

19m |

22m |

|

Total Weight |

3500kg |

4000kg |

4500kg |

5000kg |

KQ/GD150 Automatic Lollipop Production line

KQ/GD150 Automatic Lollipop Production line

| Product line name | Production Line Capacity | Actual Units Produced(Previous Year) |

|---|---|---|

| Food Processing Line | USD 5,000,000 / Year | USD 2,380,000 |

| Market | Revenue(Previous Year) | Total Revenue (%) |

|---|---|---|

| North America | USD 142,800 | 6.0 |

| South America | USD 95,200 | 4.0 |

| Eastern Europe | USD 190,400 | 8.0 |

| Southeast Asia | USD 190,400 | 8.0 |

| Africa | USD 714,000 | 30.0 |

| Oceania | USD 47,600 | 2.0 |

| Mid East | USD 476,000 | 20.0 |

| Western Europe | USD 23,800 | 1.0 |

| Southern Europe | USD 23,800 | 1.0 |

| South Asia | USD 357,000 | 15.0 |

| Domestic Market | USD 119,000 | 5.0 |

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Hydraulic Plate Cutting Machine | QC12Y-12*4000 | 1 | 5.0 | Acceptable |

| Hydraulic Plate Bending Machine | WC67K-160/4000 | 1 | 5.0 | Acceptable |

| Lathe | C6150/C6146A | 2 | 5.0 | Acceptable |

| NC Milling Machine | ORB-6SH | 2 | 1.0 | Acceptable |

| Welding Machine | MX320 | 10 | 5.0 | Acceptable |

| Planing Machine | No Information | 1 | 5.0 | Acceptable |

| Drilling Machine | Z3050*18 | 1 | 5.0 | Acceptable |

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Vernier Caliper | 0-150, 0-300 mm | 4 | 2.0 | Acceptable |

| Outside Micrometer | 0-25/0.01 mm | 2 | 3.0 | Acceptable |

| Ruler | 0-1000, 0-2000 mm | 5 | 2.0 | Acceptable |

1.Cutting

1.Cutting 2.Bending

2.Bending 3.Lathing

3.Lathing 4.Milling

4.Milling 5.Drilling

5.Drilling 6.Assembly

6.Assembly 7.Welding

7.Welding 8.Polishing

8.Polishing 9.Final Product

9.Final Product

| Certified Picture | Certification Name | Certified By | Certificate No. | Product Name & Model No. | Available Date-Expired Date |

|---|---|---|---|---|---|

|

CE | ENTE | 101011/KSF767 | Wafer Production Line & KQ/WF27, KQ/WF39, KQ/WF45, KQ/WF51 | 2010/10/01 --- 2049/12/31 |

|

CE | ENTE | 101011/KSF768 | Chocolate Production Line & KQ/CH200-I/CH200-II, KQ/CH200-III, KQ/CH200-IV | 2010/10/01 --- 2049/12/31 |

|

CE | ENTE | 101011/KSF766 | Biscuit Production Line & KQ/BC300, KQ/BC400, KQ/BC480, KQ/BC600, KQ/BC800,KQ/BC1000, KQ/BC1200 | 2010/10/01 --- 2049/12/31 |

|

CE | ENTE | 101011/KSF769 | Candy Production Line & KQ/CD150, KQ/CD300, KQ/CD400, KQ/CD450, KQ/CD600 | 2010/10/01 --- 2049/12/31 |

|

CE | ENTE | 101011/KSF770 | Cake Production Line & KQ/CK600, KQ/CK800, KQ/CK1000 | 2010/10/01 --- 2049/12/31 |

For more useful information, please feel free to contact with me.

email:hflzhs@hotmail.com

skype:hflzhs

mobile phone:86-18930197459