Brief Introduction

The materials are crushed under the effect of ultrasound vortex and high frequency vibration generated by the impact force,shearing force and the blade.The materials are sucted into the milling chamber under the negative pressure,and then are impacted,cutted and grinded under the effect of the large air flow between the blade and module,the quantity of heat is taken away by the air flow so that do not heating-up.

There is no dust in the process of the crushing,because we install the dust removal system,,the fine dust will be sucted into this chamber,so your workshop will not be suffered from the pollution of dust.

greatest Advantage

1, High output and efficiency: This pulverizer can grind the white granulated sugar,spices,salt and so on, it has the greatest advantage in the field of grinding the white granulated sugar,the output can up to 1.5ton/h-2ton/h,the fineness can up to 50mesh-150mesh.

2, Discharge continuously:be equipped the pneumatic discharge,the powder can be discharged with constant speed and continuation.

3, Without dust pollution:This equipment with medical filter element dedusting, manufacturing process without dust pollution,so meet with the GMP standard.

4, Spare parts hardly be breaked: The constantpitch is 2cr13,and the dental lamina and saw blade are made by bearing steel and have heat treatment . so only the screen mesh is breaked easily.

5, The fineness can be adjutable.

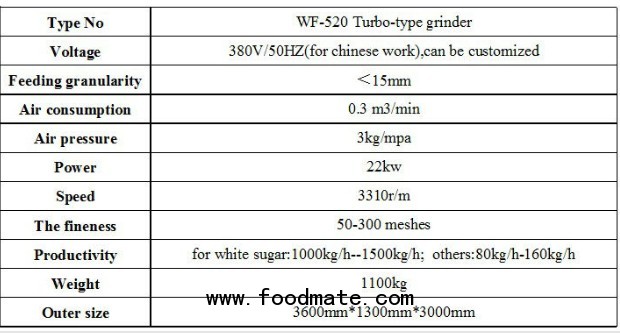

Technical Parameter