1 :Usage: To processing Doritos/Tortilla/Corn chips,and other snacks slanty food

2.Fully Automatic production line

3 .Muti-fuctional: snacks,pet food.macaroni

1.Product Description

The Tortilla /Doritos/Corn chips are kinds of snacks made from corn powder, which are cut and then fried. The main raw materials are corn powder, vegetable oil, salt and water. Although usually made of yellow corn(as pictured), they can also be made of white, or red corn. After frying and flavoring, we get very crunchy triangle or other shapes chips which are popular with both children and adult.

"Low cost, high profits" is the suitable generalization of Snack food business line, especially for puff snack food productioncan produce many kinds of snacks/puffedd snacks such as crispy rice flakes,core-filling snacks,cereal porridge,nutritional powder(instant porridge) etc.

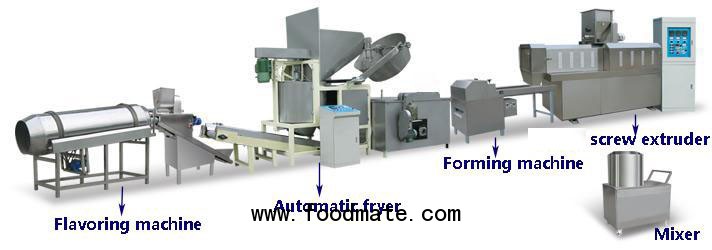

2.Doritos/Tortilla/Corn chips making machine

Flow chart:

1.Mixer

2.Screw hoister

3.Double screw extruder

4.Core filler

5.Muti-function shaper

6.Hoister

7.Dryer

8.Flavoring machine

3:Production Capacity:

100-150kg/h,150-180kg/h,200-260kg/h

4.Raw material

Corn Flour,rice flour,starch and other grain flour etc.

5.Final Product:

6.Machine Details:

7.This equipment has the wide material,multi-shape products and flexible collocations.We can produce the different products according to the different models (pellet, flower,star , ring , moon , ball , stick,ainimal or grain )and collocations.

"Low cost, high profits" is the suitable generalization of Snack food business line, especially for puff snack food productioncan produce many kinds of snacks/puffedd snacks such as crispy rice flakes,core-filling snacks,cereal porridge,nutritional powder(instant porridge) etc.

.Details of Extruder:

|

Device Name |

Twin-screw extruder |

|||

|

Model |

DL56-III |

DL65-II |

DL70-II |

DL85-II |

|

Device parameters |

||||

|

Input Voltage |

380V/50HZ |

380V/50HZ |

380V/50HZ |

380V/50HZ |

|

Installed Capacity |

35KW |

46KW |

60KW |

90KW |

|

Power Consumption |

22KW |

30KW |

45KW |

55KW |

|

Output |

120-150Kg/h |

150-180Kg/h |

180-220Kg/h |

300-500Kg/h |

|

Size |

2.5×0.8×1.8m |

3.5×1.0×2m |

3.6×1.0×2m |

4.5×1.1×2.3m |

|

Equipment Introduction |

||||

|

Machine consists of feeding system, extruding system, peeling systems, heating system, transmission system, |

||||