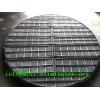

Oil Mist Eliminators or filter out oil mist created by machines before the mist is expelled into the ambient environment. Oil mist is created by machines mechanical action such as: vacuum pumps, compressor pumps, gears, transmissions, reciprocating engines, turbines, etc. Oil mist is a potential health and environmental hazard. Additionally, oil mist creates an oil build-up or residue on everything within the machineries environment.

Some machines, such as oil-sealed pumps are used and are oil mist free and the need for an oil mist eliminator is not needed. When choosing an oil mist eliminator, the following should be considered and determined.

Volume and capacity of oil mist: Oil mist eliminators have limitations as to how much gas can flow through them. Exceeding the rated or design limits of an oil mist eliminator is not recommended. Selecting or designing a oil mist eliminator for up to 3 time the expected run or operating capacity is recommend:

Oil mist produced by a machine often contains more than oil but it also contains many other contaminants and harmful chemicals. Additional features that prevent exhaust of these contaminants should be included.

Consider the maintainability of any oil mist eliminator. Systems that require a new paper filter, or excessive routine maintenance should be avoided. Keep in mind that a low maintenance system may actually be more expensive, but costs less over the like cycle of the machine.

Oil mist eliminator application samples:

Chemical and Chemical Plasma Series

For mechanical pumps

Pump-aggressive gases encountered in plasma etching

Oil that condenses in the second group does not recycle back to the pump but remains in the mist eliminator's body

Sight glass enables operator to monitor the quantity of oil retained

Hermetic Series

For hermetically sealed mechanical pumps

Made of stainless steel

Helium leak checked to extremely low leak rates before shipping

Use when pumping precious or exotic gases in a closed loop

Oil mist eliminators improve the air quality in the vicinity of the air intake, which in turn helps to maintain power output and reduces the frequency of air filter replacement as a result of oil fouling.

Integrated Air Systems can provide a fully built bespoke system and installation package for your factory/manufacturing plant.

Thousands of liters of oil can be lost from an installation over a period of a year due to oil mist emissions. The cost of replacing expensive turbine oil can be greatly reduced by returning the recovered oil back to the system.

Oil mist eliminators reduce the capital cost of an installation by minimizing the need for complex venting and pipework installations.

Eliminates all visible oil mist

Suitable for gas turbines, steam turbines and diesel engines

Discharges clean air to atmosphere

Eliminates oil stains, reduces environmental pollution – improves site conditions

Can be mounted away from the source at a convenient location

The units can be floor or machine mounted

These units are based on our proven design as supplied to a number of Beverage Can Plants over the past years.

If you are interested this that you can contact us via info@mist-eliminator.org