Processing of Aluminum Sound Insulation Foam:

Different colors of aluminum foam panels can be made. It is not only acoustic materials but also beautiful material.

For the production of foamed aluminum, AL powder is mixed with a product releasing gas at higher temperature and then compacted, this foaming agent is placed into a mold form and heated up until the agent starts to foam. Immediately thereafter the mold is taken out of the furnace and cooled off, so the aluminum foam part is frozen in shape. The outcome of this process is a closed cell aluminum foam showing a thin casting skin on the surface. nosie barrier/ shielding panels.

Property

Heat insulation and resistance, non-inflammable;

Absorption of high impact energies, regardless of the impact direction;

Highly efficient in sound absorption, electromagnetic shielding and vibration damping;

High stiffness at very low density.

Application

Aluminum foam (Closed cell) to qualify for specific requirements within the automotive, aviation, highway, railway and engine building industry. Aluminum foam is also qualifying for other high potential applications in the field of Architecture and Design, where electromagnetic shielding, structural damping, flame resistance and a decorative surface structure is required.

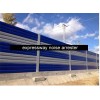

The aluminum foam can be used together with galvanized soundproof modular fence panels made from high quality steel tubing and wire mesh. The panels are cold galvanized and powder coated with polyethylene for superior rust protection. hot dipped galvanizing and custom colors are available upon request.

soundproof fencing top clips one side solid square bar, one side solid round bar with solid square bar connector. cold galvanized and powder coated.

Soundproof modular fence gates cold galvanized, powder coated fencing panel with embeded door. Door up to 8 feet high. designed to be lockable.