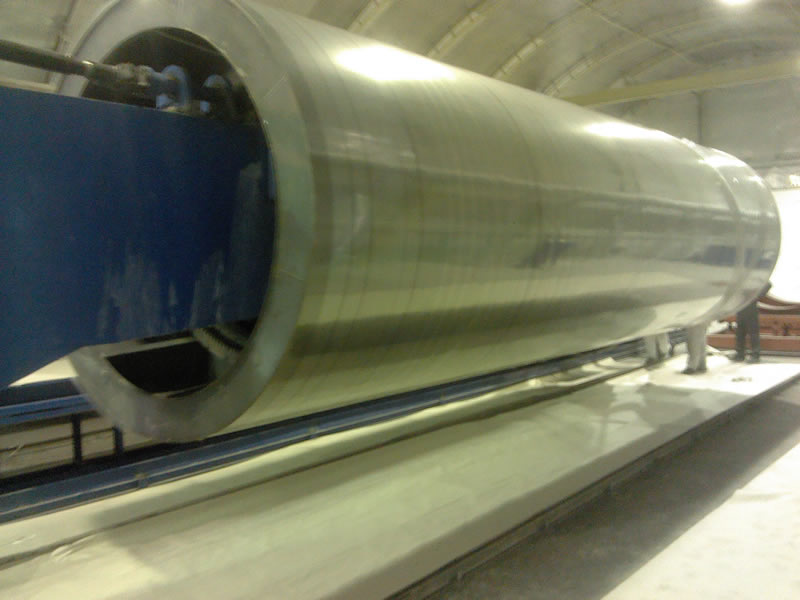

Equipment configuration: main components of horizontal winding equipment: equipment head frame, equipment tailstock, drum, track frame, winding trolley and walking track, dipping equipment, roving creel and roving guiding system, computer control system, mould Group (customized according to customer needs).

Main technical parameters and characteristics:

1. Winding diameter range: φ4000~φ10000

2. Maximum height of the tank: 12000

3. Max speed of trolley: 45m/min

4. Maximum width of the yarn: 200mm

5. Winding angle range: 0°~ 90°

6. Total equipment capacity: 17.5KW±5KW

7. The largest occupied area of equipment: 20000mmX20000mm

8. Features: Due to the limitation of transportation capacity, all large-scale storage tanks with a diameter of more than 4m have become the difficulties of the processing party and the custom-made party. In order to meet the needs of users, our company has developed the FW-10000 type micro-controlled horizontal field winding machine. The structure of the machine is combined, it can be assembled and disassembled, the equipment is distributed to the user, and then according to the requirements of the user, the winding machine is installed next to the foundation of the storage tank to complete the winding production of the large FRP storage tank.

Main parameter

1. The range of the applied diameter DN1000~DN4000mm

2. Max length can be wound: 10000mm

3. Rotating speed of the main shaft 0-20r/min

4. The max speed of pulling yarn ≦120m/min

5. The maximum width of yarn slice 220mm

6. Winding angle 45°~90°

7. 2.7Total capacity 16KW

8. Productivity 1300㎏/h

9. Occupied area 20m * 16m