Application:

Extruded plastic geogrid functions in area /Ground stabilization, pavement base reinforcement, working & load transfer platforms, rail track-bed stabilization and reinforced granular foundation beds. Mainly used in dyke and roadbed, side slope, tunnel wall, large airport, parking lot, pier freight yard construction projects. Plastic geogrid offers permanent load bearing in concrete constructions.

Benefits of using plastic geogrid fabrics:

1. Increase the bearing capacity of the roadbed and foundation and prolong their service life.

2. Prevent road surface and foundation from sinking or flawing, keep clean and beautiful ground surface.

3. Convenient construction saves time and labor, reduce mounting time and decrease maintenance expense.

4. Prevent culverts from flawing.

5. Enhance earth slope and prevent water loss and soil erosion.

6. Decrease underlayer thickness and save manufacturing cost.

7. Enhance the stability of side slope turf net patch to improve greening.

8. replac wire netting used in mine as intermediate ceiling netting.

Plastic geogrid mesh features:

High tensile strength at both longitudinal and transverse direction

Improved bearing capacity of foundation

Anti cracking and subsiding

Less cost and maintaining expense

PP Geogrid Fabrics

Material: Polypropylene / PP

Tensile strength:15-15KN/M

Elongation:13%

Mesh size:20*20mm

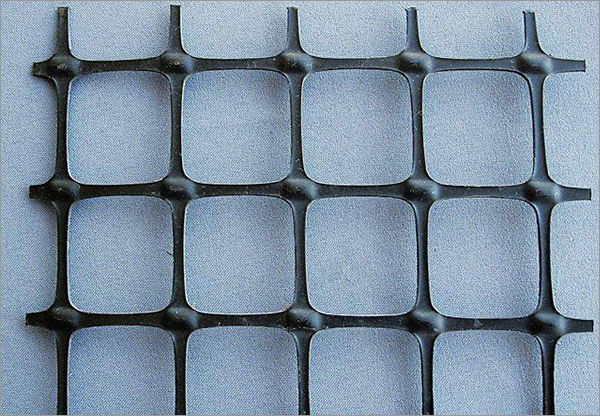

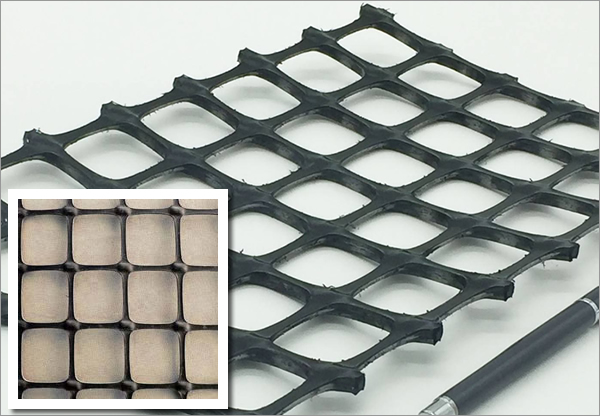

Biaxial Geogrids

Polypropylene biaxial geogrid is extruded into sheet and then punched into regular mesh pattern,and finally stretched in longitudinal and transverse directions.

Polymer Geotextile Grid used as roadbed reinforcement netting for permanent load-carrying foundations of large areas:

Mesh: Square; color: Black; material: Polymer

Uniaxial Geogrid fabric for earthwork

PP / HDPE geogrids and geosynthetics with high molecular polymer as main raw material. Uniaxial plastic geogrid has the structure with high tensile strength. Produced with higher standard over the international level(elongation at 2%~5%).