The perforating of liners are done with laser cutting process without contact operation. This process can effectively avoid undesirable factors which will cause the deformation of the base pipe. Laser cutting process uses windows interface for easy operation and accurate calculation.

Perforated liner geometry consists of stamped length, stamped width, line density and perforating distribution. All these parameters can be bespoken to achieve the required open area. For example, multiple staggered pattern or gang pattern significantly increases the open area compared with single cut pattern.

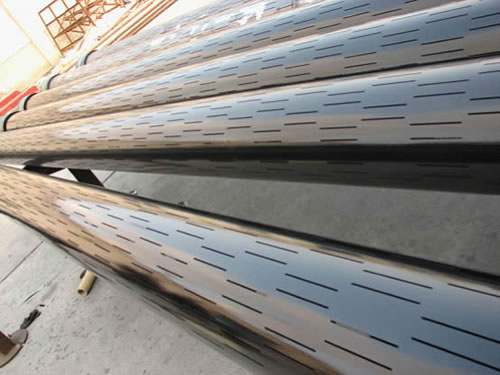

Staggered perforated liner, single line patterns

Three stamped liner patterns -straight, staggered and gang - are supplied. Each has its own characteristics.

|

|

|

| Straight line pattern | Staggered pattern | Gang pattern |

Perforated Liner Geometry

Stamped line shapes are classified into two types: straight cut slot and keystone slot. Compared with straight slot, keystone slot has higher resistance against plugging for its inter size is larger than the surface size. Once the sand entering the keystone slot, the possibility of clogging will dro sharply.

|

|

| Straight cut line | Keystone slot |

Features:

Moderate cost

Ease of installation

Sufficient operation load

Non-plugging

Laser cutting process

Product specification

|

Required slot per ft. for 3% open area |

|||||

|

Slot Width (mm) |

Slot Width (inch) |

3.5" Liner |

4.5" Liner |

5.5" Liner |

7" Liner |

|

0.38 |

0.015 |

176 |

228 |

276 |

352 |

|

0.45 |

0.018 |

148 |

188 |

232 |

296 |

|

0.5 |

0.020 |

132 |

172 |

208 |

264 |

|

0.63 |

0.025 |

108 |

136 |

168 |

212 |

|

0.7 |

0.028 |

96 |

124 |

148 |

188 |

|

1 |

0.038 |

52 |

68 |

84 |

104 |

|

1.5 |

0.058 |

36 |

44 |

56 |

68 |

|

3 |

0.125 |

16 |

24 |

28 |

32 |

|

6 |

0.250 |

8 |

12 |

16 |

16 |