Advanced technology enabled the distillation of later spirits. The first book on distillation was published by the Germans in 1500, but at that time this process was used to make perfume or medicine. Only 100 years later, people began to pay attention to the idea of drinking for pleasure. However, in the 19th century, modern forms of distillation were born!

Step 1: Obtain your device

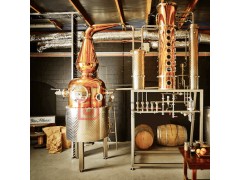

The distiller works on the distiller and can be a tank distiller (the oldest distiller type) or a column distiller. This is a complicated machine with the columns extending all the way to the ceiling. The distiller is connected to the condenser (the container through which the cooling water passes), and the condenser is connected to the barrel to collect the finished distillate.

Step 2: Clean the distiller

Your distiller must be cleaned thoroughly before each distillation. After all, you don't want the dirt from the last distillation to mess up your gin!

Step 3: Add alcohol and botanicals

There are many unique distillation techniques, usually developed by the distiller after months and years of experimentation. But the basic principle remains the same: first add vegetable and alkaline alcohol (also called "neutral alcohol") to the still. This spirit is a fermented alcohol, usually made from grains without added flavors. It is a mixture of water and pure alcohol.

Step 4: Heating

The heat source-some distillers use an open flame, while others use a furnace or electric heat source-start heating the bottom of the distiller. Alcohol starts to boil at 73 degrees Celsius, while water does not boil until it reaches 100 degrees Celsius. This means that the alcohol in the neutral spirits will turn into gas and start to rise, while most of the water will stay at the bottom of the still.

Step 5: Cool down and capture

As a gas, the alcohol passes upward through the distillation head, tank top, or distillation tower. It then passes through a condenser filled with cold water, where it cools and turns back into liquid. The final distillate drips into the barrel, where the distiller can decide whether to keep it or return it to the distiller for a second round of distillation to become a higher concentration of water and alcohol solution.

Contact us

A wide range of models can meet the various requirements of each market and ensure that you can always find a solution that suits you. If you want to know more detailed information about our equipment, please contact us.