Summary of test method

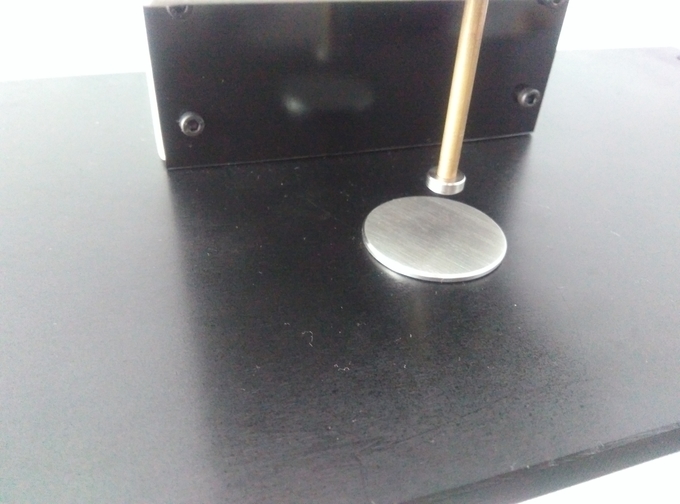

A specimen is placed on the base and a weighted presser foot lowered. The displacement between the base and the presser foot is measured as the thickness of the specimen.

Features

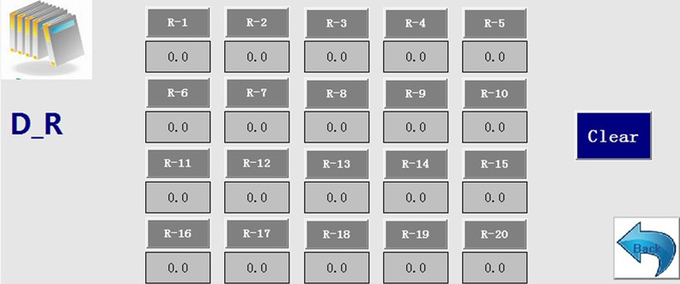

- PLC control and touch screen operation

- Contact area and pressure are standards conformed.

- Presser foot automatic lifting

- Real time display of maximum, minimum, average and standard deviation

- Data auto statistics, storage and micro printing

- RS232 port and software (Optional)

Technical data

Test Range 0~2mm(Customization available)

Resolution 0.1 μm

Measuring pressure 17.5±1 KPa (for film); 50±1 KPa (for paper, optional)(flat foot)

Contact area 50 mm2 (for film); 200 mm2 (for paper, optional)(flat foot)

Power AC 220V 50Hz (Customization available)

Dimensions 450mm(L)*350mm(W)*400mm(H)

It complies with the following standards:

ASTM D374-99: Standard Test Methods for Thickness of Solid Electrical Insulation

ASTM D1777: Standard Test Method for Thickness of Textile Materials

ISO 4593: Plastics; Film and sheeting; Determination of thickness by mechanical scanning

ISO 534-2011: Paper and board -- Determination of thickness, density and specific volume

ISO 3034:2011: Corrugated fibreboard -- Determination of single sheet thickness

TAPPI T411, JIS K6250, JIS K6783, JIS Z1702, BS 3983, BS 4817