By attached between the antenna and the back metal, forming a magnetic conduction channel, which can eliminate the interfere to antenna from metal (or other sources of interference), enable the antenna to transmit a signal normally.

The invention of emi shielding sheet provides a solution for the electromagnetic shielding of FPC, with good application effect, emi shielding sheet can effectively suppress electromagnetic interference, and at the same time, it can reduce the attenuation of transmission signals in FPC, and reduce the incompleteness of transmission signals. It has become an important raw material of FPC and is widely used in electronic products such as smart phones and tablet computers. We are a professional emi shielding sheet manufacturer, if you are interested in our products, please contact us.

The principle of emi shielding sheet

- When the electromagnetic wave reaches the surface of the shield, the reflection of the incident wave is caused by the discontinuity of impedance at the interface between the air and the metal. This kind of reflection does not require that the shielding material must have a certain thickness, but only requires the discontinuity on the interface to reflect the incident wave. This kind of reflection does not require the shielding material to have a certain thickness, only the discontinuity at the interface.

- The energy that is not reflected by the surface and enters the shielding body is attenuated by the shielding material during the forward propagation in the body. Also known as absorption.

- When the residual energy that has not been attenuated in the shield body is transmitted to the other surface of the material, it encounters the interface with discontinuous metal-air impedance, which will form a re-reflection and return to the shield body. This reflection may have multiple reflections at the interface of the two metals. In a word, the attenuation of electromagnetic waves by emi shielding sheet is mainly based on the reflection and absorption of electromagnetic waves.

Application

Anti metal tag / card

NFC mobile phone battery / rear lid

Anti metal card reader

Iphone protective sleeve

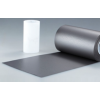

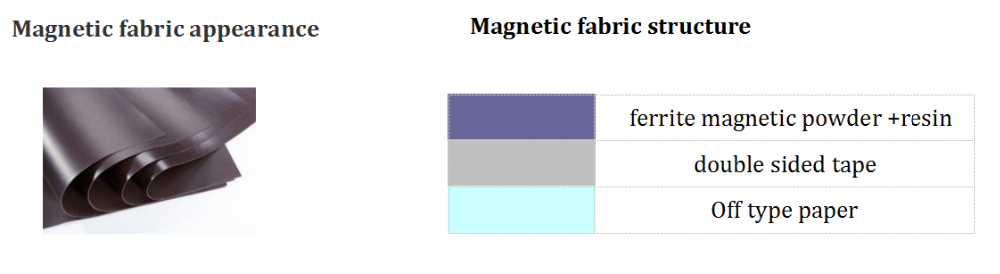

Characteristic of Magnetic fabric

Low cost

General permeability, low magnetic loss

High resistivity

Meet ROHS and halogen free

Flame retardant grade:UL94-V2

Common thickness:0.3~0.5mm

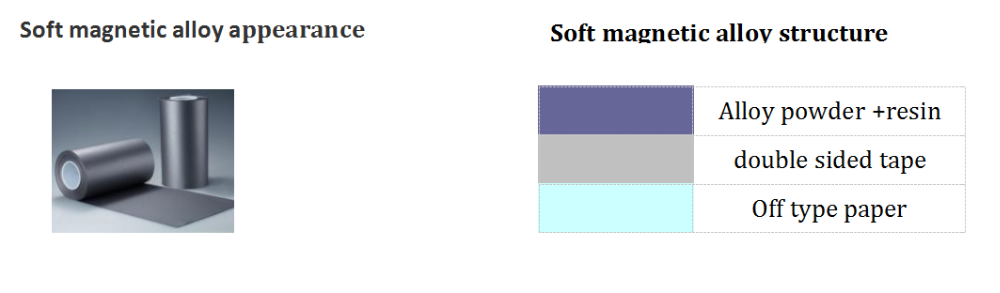

Characteristic of Soft magnetic alloy

Middle and upper cost

Middle and upper permeability, low magnetic loss

High resistivity

Meet ROHS and halogen free

Flame retardant grade:UL94-V2

Common thickness:0.05~0.5mm

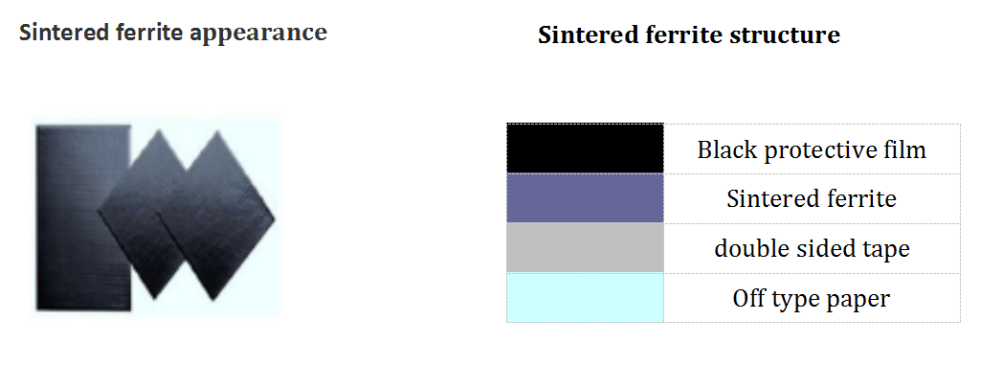

Characteristic of sintered ferrite

High cost

High permeability, low magnetic loss

High resistivity

Meet ROHS and halogen free

Flame retardant grade:UL94-V2

Common thickness:0.06~0.1mm

Features of emi shielding sheet

- Soft texture materials, good fit;

- Perfect absorption performance, can absorb the electromagnetic wave in the wide band range;

- Meet the ROHS environmental protection requirements;

- Can be cut into required size and shape based on customer requirements;

Company certification:IS09001

Product certification:ROHS and Halogen Free

Guarantee period:5 years

Wave-absorbing material in RFID anti-metal label application

After more than ten years of development in China’s RFID industry, now the technology has been relatively mature, especially in the past two years, under the background of the country actively encouraging and vigorously promoting the healthy development of the industry, with the continuous promotion of the Internet of things, it has maintained a steady rising development trend.

The industry has also reached a consensus on the frequency standard formulation of RFID. At present, the international frequency of 13.56MHz,13.56MHz high-frequency RFID technology has a stable performance and reasonable price, matching its reading distance range and practical application distance range, so it is widely used in bus card and mobile phone payment.

The RFID anti-metal electronic tag is used under the 13.56MHz, which usually has a maximum read and write distance of about 10 cm, and the chip’s current consumption is about 1 ma. Because as the frequency increases, the inductance of the required electronic tag coil shows a decrease in the number of coil turns, usually where the typical number of turns is 3 to 10 turns.

The RFID tag-reading card distance is not only related to itself, but also has a lot to do with its environment. When using inductively coupled RFID systems, it is often required that a reader or electronic tag antenna be mounted directly on a metal surface. However, it is not possible to install a magnetic antenna directly on a metal surface.

RFID electronic label is often used in metal environment. When RFID electronic label is close to metal, because the metal is strongly reflective to electromagnetic waves, so it will be accompanied by the signal weakening, the card distance will become closer, serious interference will appear card failure phenomenon. The current common solution is to put a layer of wave-absorbing material on the back of the electronic label.

Application of ferrite in NFC coils or antenna plates

Ultra-thin sintering NFC ferrite sheet brief introduction: 13.56MHZ antenna ferrite sheet / film is a high temperature sintering ferric oxide material. In handheld devices such as payment mobile phones, the main function of electronic labels is to reduce the absorption of the signal magnetic field, and the ferrite film itself is a high-temperature sintering ferrite material, which effectively increases the induction distance by increasing the magnetic field strength.

1. Effect of ultra-thin sintering NFC ferrite tablets:

Near-field communication, Near Field Communication (abbreviated as NFC) technology has attracted wide attention with its advantages of high transmission bandwidth, high security and low energy consumption. At present, the mobile phone one-card based on this technology has begun to emerge, and the use of NFC mobile phone to open the door, parking, mobile payment and other ways has become a new fashion of consumption.

2. Application field of ultra-thin sintering NFC ferrite tablets:

In terms of efficacy, ferrite magnetic sheet is mainly used to prevent NFC communication signal from being absorbed by metal, battery; increase the magnetic field strength of antenna and effectively increase the communication sensing distance. In terms of product quality assurance, the perfect material control and quality system make its product performance reach the level of the same series of products in Japan and South Korea, and fully meet the NFC communication distance requirements.

Sum up:

Ferrite film: effectively improve the performance of NFC antenna products can bend by increasing the magnetic field intensity of the antenna, effectively increase the induction distance;

Main application of ferrite tablet: NFC function of mobile phone non-contact IC card RFID read / writer / RFID tag.