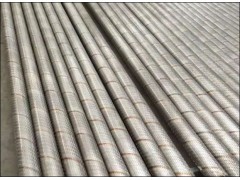

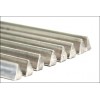

PPS screen is the primary element for sand control water well screen which consists of perforated base pipe, stainless steel filtration jacket with punched slot, and backup ring. The base pipe is of API casing or API tubing with many drilled holes. The filtration jacket with punched slot is made of high quality stainless steel, and the spatial slot in high dense array over it is achieved by digital control precise punching. In the end, the filtration jacket with punched slot is welded onto the perforated base pipe through backup ring.

We supply following Precise Punched Slot (PPS) Screens.

Precise Punched Slot (PPS) Screen

6 5/8”, 23- 26 lb/ft, N 80, BTC

Specification:

PPS (Precise Punched Slot) Screen, Stainless Steel 304 screen jacket with support ring, open size 300um, 65/8”base pipe, N-80, 8.94mm, BTC thread, Perforation 200 holes/m.

Screen Jacket: Stainless steel 304, 1.5 mm thick.

Slot width 0.30mm, slot Length 10mm, slot density 2 slots in20mm*8mm.

105 Slots in Circle, 6100 slots per meter, uniformly distributed.