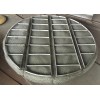

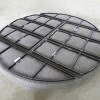

A baffled type mist eliminator is a device designed to reduce the amount of mist, droplets, aerosols, and other contaminants in gas or liquid streams. It consists of a series of baffles or plates arranged in a specific pattern to facilitate the separation of droplets from the gas stream. Baffled type mist eliminators are usually made from plastic, metal, or ceramic materials and can be manufactured in a variety of shapes and sizes.

The production process of a baffled type mist eliminator starts with designing and fabricating the device. This involves selecting the materials and manufacturing the components according to the design specifications. Next, the device is assembled, tested, and installed in the process line. The device is then monitored for proper operation and any necessary adjustments are made.

Baffled type mist eliminators can be made from a variety of materials, such as metals, plastics, and ceramics. metals are typically used for larger, more complex designs, while plastics and ceramics are usually used in smaller devices. The profile of the device will depend on the material and the required performance. The number of baffles and their size and shape can also affect the performance of the device.

The common parameters used to characterize a baffle-type mist eliminator. These include the flow rate, pressure drop, collection efficiency, and droplet size. The flow rate is defined as the volume of liquid or gas passing through the device in one minute. The pressure dro is the difference in pressure between the inlet and outlet of the device. The collection efficiency is the percentage of particles or droplets that the device can separate from the gas stream, while the droplet size is the maximum size of droplet the device can capture.