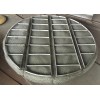

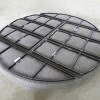

High permeability demister pads are used in a wide range of applications, including air conditioning, chemical processing, and oil-water separations. The process for production involves the use of advanced equipment and methods to create the right size and shape of product in order to ensure the highest degree of performance.

High permeability demister pads are used in a variety of industries and applications. In air conditioning, they are used to minimize water vapor condensate, while in chemical processing they are used to separate solid particles from liquids. Additionally, they are used in oil-water separations to improve the efficiency of systems.

The permeability of demister pads is determined by the size of the openings in the material, as well as the density of the weave. The larger the size and density of the weave, the more efficient the separation will be. Additionally, the thickness of the material is a key factor in determining permeability as well. It is important to choose the right material and mesh size to ensure optimal efficiency.

Materials:

Demister pads come in a variety of materials such as polypropylene, stainless steel, carbon steel, and other alloys. Depending on the application, the material chosen must be able to withstand adverse conditions that may affect performance. Polypropylene is typically used for filtration of air and light gases under normal operating conditions. However, for higher temperature, corrosive, and high pressure applications, stainless steel or carbon steel can be used.