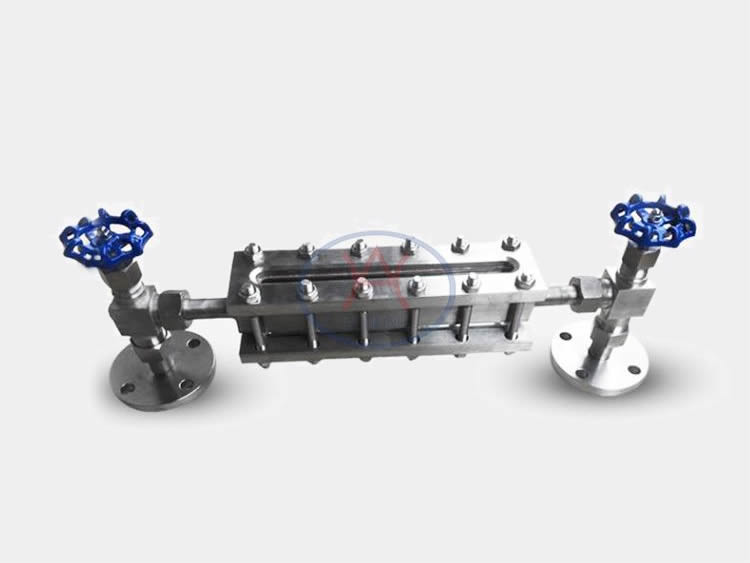

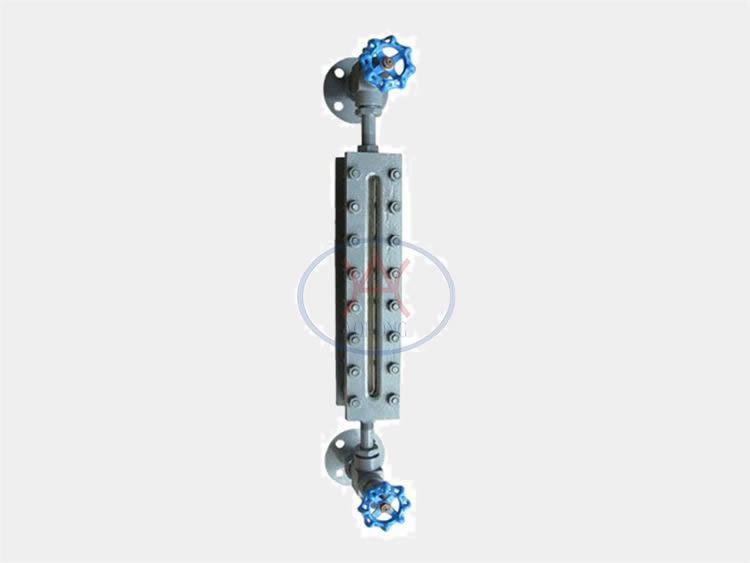

Transparent level gauge for fluid monitoring

Transparent Type Glass Plate Level Gauge

Working Principle

Transparent Level Gauges operate with two plate glasses between which the fluid resides. The level is indicated due to the differing transparency of the fluid and gaseous states, and in some cases, a light source located behind the gauge illuminates the separation surface, enhancing visibility. This light is completely reflected downward, providing a clear view to the observer.

Applications

Transparent Level Gauges find broad applicability across industries wherever fluid level monitoring is necessary. This includes installations where the use of protective mica or Polytrifluorochloroethylene shields is necessary to protect the gauge glass from corrosive fluids. Additionally, they are ideal for observing interfaces and color changes in the fluid, making them suitable for water/steam applications and monitoring colorless, highly fluid substances.

Advantages

These gauges offer several benefits, such as versatility for a wide range of installations and compatibility with protective shields for increased durability. Their design allows for the observation of interface and fluid color, providing critical information about the process fluid. Furthermore, the inclusion of safety ball-check devices in cross-fittings or shut-off valves prevents leakages, enhancing safety and reliability.

Information

Typically, valves are fitted between the gauge and its connecting ends, allowing for easy disassembly without needing to empty the vessel. Furthermore, Transparent Level Gauges can be customized with various connection options, including flanged, threaded, or welded ends. This adaptability ensures that they can fit seamlessly into your specific installation requirements.