Introduction:

XBF-III automatic the small noodle production line is my company based on research of similar products at home and abroad, combined with the needs of the mass consumer market in China, the development, the production of miniaturized production features a new generation of products. Perfect technology, compact structure, novel design, reliable performance. Production from flour to finished products automatically once completed, the high degree of automation, simple operation, moderate yield, energy saving, small footprint, the investment is only one tenth of large equipment, with less investment, quick features, particularly suitable for medium small and individual businesses.

The production line of corrugated instant noodles, rehydration time is short, good elasticity, smoothness and transparency, comparable with large market popular equipment.

The Company is responsible for the installation, commissioning equipment, training staff until the production of qualified products; process recipe, spices, agents printed bags.

Voltage:Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

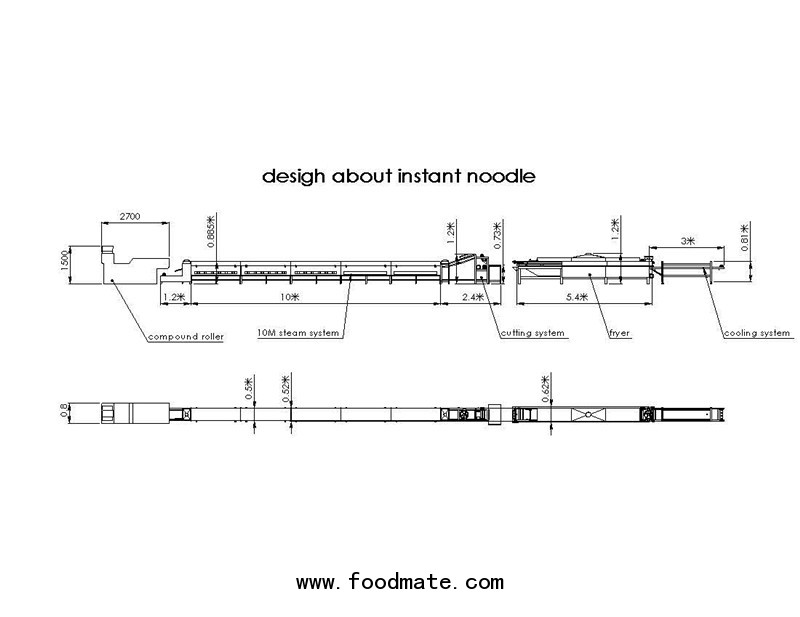

Extruded Instant noodles Productions Flow-chart

Process Flow

Dough maker----Roller pressing machine---Bolling machine---Cutting machine---Electric fryer---Cooling machine---packing

Technical parameter

|

Model |

XBF-III Electrical instant noodles line |

XBF-III Steam instant noodles line |

|

Installed capacity |

154kw |

4.2kw |

|

Steam pressure |

1.5kg/cm² |

6kg/cm² |

|

Acting width |

210mm |

210mm |

|

Output |

111000pcs/8h |

11000pcs/8h |

|

Size |

26000*700*1500mm |

26000*700*1500mm |

The detailed information for instant noodles processing line

|

No |

Name |

power |

Output |

Size |

Function |

|

1 |

Mixer |

3kw |

180 kg/h |

2200*900*1450mm |

to mix the material such as the wheat flour and waster |

|

2 |

Roller pressing machine |

4kw |

150 kg/h |

2300*700*1450 mm |

To make noodle-shaping |

|

3 |

Boiling machine |

84kw |

150 kg/h |

21000*1400*1900 mm |

To boil the noodle |

|

4 |

fryer |

90kw |

150 kg/h |

5400*870*1200mm |

To fry the instant noodle |

|

5 |

Cooling machine |

3kw |

200 kg/h |

3200*700*1000 mm |

Have a cool the noodle |

1. We can provide factory layout according to customer’s factory size in advance.

2. When we received your deposit of this order, we will ask our engineers to prepare to apply the visa, when the instant noodles processing line arrived your country, and we will send two engineers to go and help you to install the corn flakes line, teach your worker(3-4 workers) how to operate the instant noodles line, until your worker know the instant noodles line well.

3. Our engineers has responsibility to teach your worker how to clean the extruder, how to change the screw, how to change barrel etc. and we have responsibility to provide technology support with you forever.

4. Our engineers can provide basic formula for producing the instant noodles and help customer to produce good quality food according customer’s detailed formula.

5. We provide the spare parts will at preferential price for an extended long time.