Inline Filters for Hot Tea Slurries

Product Introduction

China New design circular vibrating sieve screen equipment is a new-type and high efficient machine which moves circularly and has multi-layers. The machine uses the eccentric shaft vibration-exciter and the eccentric blocks to adjust the amplitude.It possesses the features of many specifications, reliability, strong exciting force, high efficiency, little noise, durability, convenient maintenance and safety.Vibrating screen machine is applied to sieveing and filtering powder, partical and liquid in different fields.

Working principle

Its vertical motor, which is installed eccentric hammers on the top and bottom, is regarded as a vibratory source. The eccentric hammers change rotation into horizontal, vertical and inclined movement, and then pass the movement to the sieving surface. Adjusting the phase angle on the top and bottom can change trajectories of the materials on the sieve.

Features

1.High screening accuracy circular Sieve Shaker

2.High efficiency powder Sieve Shaker

3.Appropriate for any power ,grain ,mucus

4.Compact structure without any dead angles

5.Easy to clean and disinfect thoroughly

6.New net frame, long use life of screen, change the sieve easily

7.Can be used in single layer and multilayer screens

8. frames can be 360 adjusted arbitrarily, suitable to apply in the production line

9.Spare parts are made of stainless steel

10.The materials discharge automatically ,can work continuously

Detailed Images

Vibration Screen Machine

Name: Bottom Base

Brand: TC

Support the whole body of vibrating screen machine, and keep the stability & balance of the equipment during the vibration condition.

The height can be customized to meet your specific demand.

Vibration Screen Machine

Name: Verticle Vibration Motor

Brand: TC

As vibration source of the equipment, it has the advantages of small amplitude and high efficiency.

Vibration Screen Machine

Name: Mesh Screen

Brand: TC

With different mesh sizes, it can help to sieve or filter different materials or grade one kind material to different fractions.

Vibration Screen Machine

Name: Buffer Plate

Brand: TC

The buffer plate can be added if you need, which can protect the mesh screen through reducing the impact force brought by fallen material.

Vibration Screen Machine

Name: Spring

Brand: TC

Protect the main body of equipment from the damage of the strong vibration.

Vibration Screen Machine

Name: The Outlet Hole

Brand: TC

Material is discharged through different outlet hole according to different size. The outlet direction can turn as 360 degree.

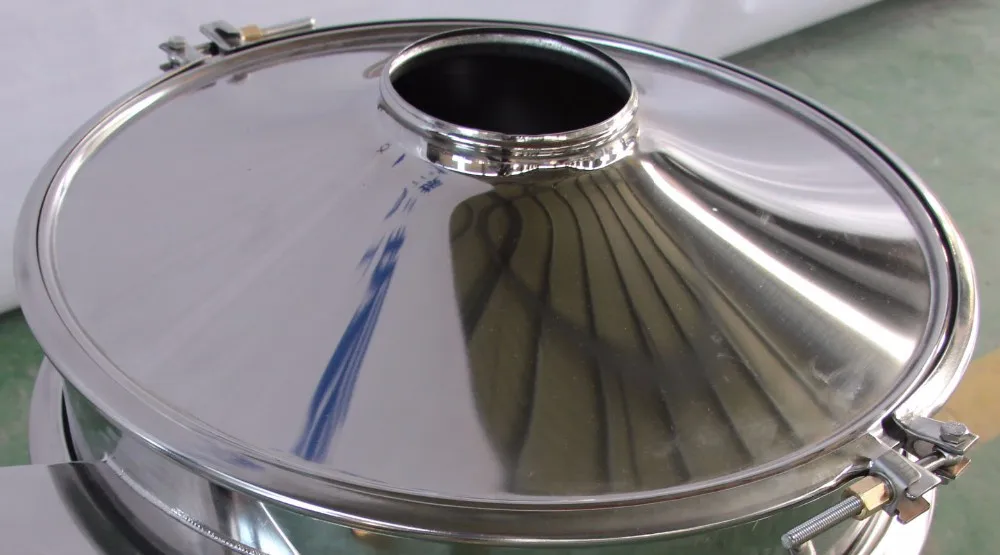

Vibration Screen Machine

Name: Screw Clamps

Brand: TC

To seal and lock screen layers tightly.

Vibration Screen Machine

Name: Inlet Hole with Dust Cover

Brand: TC

The inlet hole can be designed with enlarged size and more higher than common ones.

Other Customized Design of Vibration Screen Machine

The Application of Vibrating Screen Machine:

Three-D rotary vibrating screen can sieve and filter particle, powder, and mucus. It can be used to many different fields.

Food Industry: sugar, salt, aginomoto, alkali, starch, rice, milk powder, egg powder, soybean sauce, juice, tea, snack foods, quick-frozen food, flavoring, albumen, food additives, etc.

Pharmaceuticals Industry: industrial drug, Chinese medicine powder and liquid, western medicine powder and liquid, pill powder, pellets.

Chemical Industry: resin, paint coating, industrial drug, cosmetic, resin powder, oil paint, detergent, micro powder, sodium carbonate, lemon powder, rubber, plastic and others.

Abrasives & ceramics industry: aluminium oxide, silica sand, mud, spray soil particles.

metallurgical Industry: metal powder, titanium oxide, zinc oxide, aluminum powder, lead powder, copper powder, ore, alloyed powder, electrode powder, manganese dioxide, electrolytic copper powder, milled powder, fireproofing material, kaolin, lime, alumina, ground calcium carbonate(GCC), quarts sand, etc.

Paper-making industry: paper coating, white and mud earth, black and white liquid, liquid waste, paper-making liquid,water recovery.

Environmental protection: waste oil, waste water, pulp & paper, activated carbon, rubbish, excrement and others.