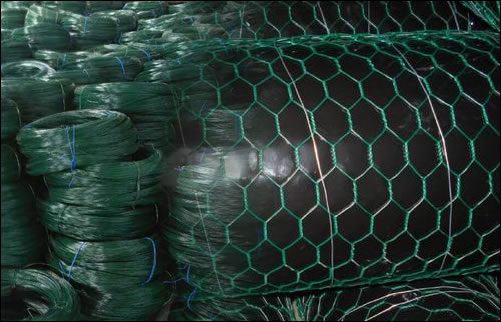

Gabion wires have different corrosion resistant finishes: Hot Dip Galvanized, Zinc-Aluminum ( Galfan) Galvanizing, and PVC coated galvanized.

Wire Galvanization and PVC coating specification

- Zinc Coating: Zinc coating to BS729 or other equivalent standard (galvanized after welding 460g/sqm). Galvanizing is stable in the PH range 7 to 10. Wire for fabrication and assembly shall be hot-dipped galvanized.

- Zinc-Aluminum: Galvanizing uses the alloy coating of 95% Zinc-5% Aluminum which has superior corrosion resistance. The coating gives approximately 1.5 to 4 times the durability of a pure zinc coating. The coating weight applied is equivalent to the coating weights specified in BS443 or other equivalent standard for zinc coating before fabrication.

- PVC-zinc Coatings: PVC coating is commonly used in manufacturing Gabions for more saline areas and water and soil PH 7 to 10. The PVC coating with 0.5 mm thickness will give a life expectancy for the structure. The PVC coating is fusion bonded to the wire. PVC coating is applied to wires pre zinc coated or zinc aluminum galvanized.

Zinc Galvanized Wire:

Galfan Galvanized Wire:

PVC Powder Coated Galvanized Wire: ( Core wire zinc galv. or galfan coated)

Heavily Galvanized Hot Dip Iron Wire Sizes and Standard

Wire Diameter: 5.59 mm (#5 gauge), 4.19 mm (#8 gauge), 3.4 mm (#10 gauge)

Tensile strength: 55 kg/mm2 (BS 1052)

Elongation: not greater than 12%

Tolerance: Comply to ASTM A-641-98

Zinc coating: Heavily galvanized (BS 443-82)

Steel Wires of different sizes are used for making different parts of mesh gabions

- For hexagonal double twisted galvanized wire mesh 8x10, wire 2.7mm mostly used as mesh wire.

Galvanized Wire 3.4 for edge wire ( reinforcing mesh wire )

Galvanized wire 2.2mm, for connecting of edges ( lacing wire) or zinc coated inner connecting wire. - For hexagonal mesh (12x10) centimeters, wires used as following:

Workable Gabion wires, the zinc coating min.260 g/m2;

Side wires of net min. (4-3.6) mm;

Internal wire of net (texture) min. (2.7-3) mm

Binding wire for Gabion box not less than (2.5-2.2) mm;

Wire wrapping for Gabion box should be according to specified specifications: The length of the Gabion cavity before extrusion not more than (10%) compere to the Gabion tested wire. - Hot dipped galvanized wire, 2.5mm diameter for hex mesh weaving: packed in 500kg big coils, mild drawn steel wire, bright surface, tensile strength 340N/mm2 to 500 N/mm2.

- Selvedge wire-8 SWG are used with mesh wire-10 and binding wire -12 SWG.

- For Net specification of 50mmX50mm net opening, wire gauge 5mm is commonly used

- For Wire Netting 80mmX80mm, wire gauge 6-8mm is commonly used.

Technical Details of Galvanized Mesh Wire, Lacing Wire and Selvedge Wire

Standard Diameter of GI Wire

2.0 mm

2.2 mm

2.4 mm

2.7 mm

3.0 mm

3.4 mm

3.9 mm

Technical Details Example ( 2.7-3 Gabion Mesh Wire and Fitting Lacing and Side Wire)

| Item | Units | Lacing Wire | Mesh Wire | Selvedge Wire |

| Galvanize wire diameter | Mm | 2.2-2.5 | 2.7-3 | 3.6-4 |

| Wire Tolerance | Mm | ±0.08-0.06 | ±0.08-0.06 | ±0.07-0.1 |

| Quantity of Zinc | g/m2 | 260-280 | 260-275 | 260-290 |

| Tensile Strength | n/mm2 | 350-575 | 350-575 | 350-575 |

| Elongation | % | >10% | >10% | >10% |

Mesh Wire for Weaving Hexagonal Nets of Various Holes (Wires Galvanized and PVC Coated)

| Hexagonal Wire Netting Gabion Mesh | |||

| Mesh (mm) |

Wire Diameter Applied GI Wire) (mm) |

Wire Diameter (PVC Coated)/ Inner/Outside(mm) |

Strands |

| 6080 | 2.0-2.8 | 2.0/3.0-2.5/3.5 | 3 |

| 80100 | 2.0-3.2 | 2.0/3.0-2.8/3.8 | 3 |

| 80120 | 2.0-3.2 | 2.0/3.0-2.8/3.8 | 3 |

| 100120 | 2.0-3.4 | 2.0/3.0-2.8/3.8 | 3 |

| 100150 | 2.0-3.4 | 2.0/3.0-2.8/3.8 | 3 |

| 120150 | 2.0-4.0 | 2.0/3.0-3.0/4.0 | 3 |

Quality Assurance

Galvanize wire for Galvanized Gabions and Baskets are made according to BS-443 code or BS-1052 specification or equal to ASTM, or BS442 Galvanized coatings on wire; BS4545 Methods for mechanical testing of steel wire.

Test results are provided.

Tests include:

Tolerance on diameter of galvanized round wire,

Ductility test: Wrapping test on round wire and bend test on round wire,

Limits for ranges of tensile strength values,

Zinc firmness and etc.

Gabion Wire Workshop