As professional supplier of quality gabion mesh machine, we provide:

Detail technical data of the facility

Guaranteed brand new production line

Wire materials for net weaving if requested

On-line and personal professional installation and production training

Parts replacement

Problem shooting

Complete production line solution

Prompt delivery and after sales services.

Setting Up a Gabion Mesh Weaving Factory

Supplied with main weaving machine, accessory machine and parts, also recommended wires, wire mesh size and gabion size for production.

Machine Technical Features:

- Machine makes netting from spring coil and bobbins;

- Bobbin Winding and Spiral Winding machine are required to run the main machine;

- Machine produces DOUBLE TWIST type wire mesh to avoid unraveling and dimensional stability;

- Machine is run by pinion on the front and rear rack of the machine;

- The wires which are fed from the bobbins and also from the spiral coil (prepared in spiral coiling machine) ;

- When the length of netting reaches the desired length, the same is cut by scissor;

- Smooth running, low noise;

- Automatically stop and

- Auto alarm signal.

- Has automatic oil system

- Has Infrared ray safety protection system

- Out put of the machine Production 750-1000 square meters per hour

- Tool box with set of tools

- Spare parts for one year

Automatic Gabion Mesh Weaving Machine

MAIN GABION MESH MACHINE LINES

The proposed machines are to make different mesh sizes. The detail specifications:

a) Mesh sizes:

50 X70 mm and multiple of it

60 x 80mm and multiple of it

b) Max. Netting width: 4300mm;

c) Max. Galvanized wire diameter: 3-4mm;

d) Max PVC wire diameter: 4.1-5.1mm;

e) Power: Approximately 22kW;

f) Size: Approximately 7200 x 1400 x 2400mm;

g) Weight: Approximately 15 Metric tons;

h) Machine output: 400 - 700 square m/hr;

i) Automatic stop system (optional) (when the coiling finished or

Wire broken, the machine will stop automatically);

j) Infrared ray safety protection system (optional);

k) Automatic oil system.

| Mesh Opening (mm) | Maximum width (mm) | Maximum wire Diameter (MM) | PVC coated wire Diam. (mm) | Out put (meter/hour ) | Overall size L x W x H (mm) | Total Weight (T) |

Motor Power (kw) |

| 50*70 | 4300 | 3 | 4 | 150 | 7200 x 1400 x 2400 |

15 | 22 |

| 60*80 | 4300 | 3 | 4 | 165 | 15 | 22 |

HEAVY-DUTY HEXAGONAL NET TWISTING MACHINE LINE

| Mesh Opening(mm) | Maximum Width(mm) | Maximum Wire Diameter (mm) | No. of Twist | Speed | Motor power | weight | |

| Mesh/Min | Meter/Hour | ||||||

| 5070 | 2300 | 3 | 3 | 25 | 150 | 11 Kw | 12 tons |

| 3300 | 3 | 3 | 25 | 150 | |||

| 4300 | 3 | 3 | 25 | 150 | |||

| 6080 | 2300 | 3 | 3 | 25 | 165 | 11 kw | 12 tons |

| 3300 | 3 | 3 | 25 | 165 | |||

| 4300 | 3 | 3 | 25 | 165 | |||

COILING MACHINE

Coiling Machine serves to make wires into form of coils to be used as weft wires, on the Hexagonal Wire Netting Machine for purpose of producing hexagonal screens.

| Parameters | Values |

| No. of coiling spindles | 4 |

| Dia. of coiling shaft | 10,12,16mm |

| Suitable for wire diameters | 0.38-0.90mm |

| Total Weight | 350kg |

| Power | 1.5kw |

WIRING WINDING MACHINE

Wire Winding Machine serves to wind black iron or galvanized iron wire from bundles on Hexagonal Wire Netting Machine or Wire Screen Looms.

| Parameters | Values |

| No. of bobbin spindles | 4 |

| Suitable for wire diameters | 480 mm |

| Suitable for wire diameters | 0.38-0.90mm |

| Total Weight | 650kg |

| Power | 1.5kw |

NETTING SHEET STRAIGHTENING MACHINE

| Parameters | Values |

| Working width | 400mm |

| Wire Diameter | 5mm |

| Out put | 8.5m/minute |

| Power | 3kw |

| Roller Speed | 20 turns/minute |

| Size ( LXWXH) | 505014501600 mm |

NETTING SHEET CUTTING MACHINE

| Parameters | Values |

| Maximum Shearing Wire Diameter | 6 mm |

| Shearing angle | 10301 |

| Number of stroke | 10 |

| Power | 7.5 kw |

| Weight approximate | 10 tons |

| Size | 46401705X1700 mm |

GABION PACKING MACHINE

| Parameters | Values |

| Maximum packing size | 200010601000mm |

| power | 5.5 kw |

| Working pressure | 0.3 to 0.6 Mpa |

| Total weight | Approximately 1500 kg |

| Exterior Size | 234012003900mm |

STEEL WIRE STRAIGHTENING CUTTING MACHINE

| Parameter | Values |

| Adjusting range of wire Diameter | 3 to 5 mm , length cutting of wire is adjustable within 3.5 m |

| Moving wire speed | 28m/minute |

| Total power | 3kw |

| Exterior size | 50004001000 mm |

| Height | Approximately 300kg |

GALVANIZED STEEL WIRE FOR GABIONS MESH WEAVING

The proposed mild steel mesh wire galvanized, according to SABS 675 of 1993 standard, with the specification shown below:

| Wire Size in mm | Tensile Strength | Elongation | Galvanized amount (g/sq m) |

| 2.2 | 200-400 MP | 12% | 220 |

| 2.5 | >> | >> | 250 |

| 2.7 | >> | >> | 260 |

| 3.0 | >> | >> | 260 |

| 3.4 | >> | >> | 260 |

GABION WIRE MESH MACHINE is used to produce following hexagonal netting products:

The machines are to produce galvanized and PVC coating Gabion.

For galvanized mesh, the diameter of the wire shall be 2.2 mm-4.0mm.

For PVC coated hexagonal wire, the wire with coating, diameter from 3.0 mm to 4.5 mm.

Recommended aperture size for the hexagonal wire mesh and diameter for wire to be used in the proposed factory is indicated on the table below.

| Nominal aperture size ( Mesh opening) in MM |

Wire gauge in mm | The inner wire diameter / outer wire diameter in mm | Roll width(M) |

| 50 * 70 | 2.2-3.0 | 2.2/3.2-3.0/4.0 | 4.3 |

| 60* 80 | 2.4-3.5 | 2.4/3.4-3.2/4.2 | 4.3 |

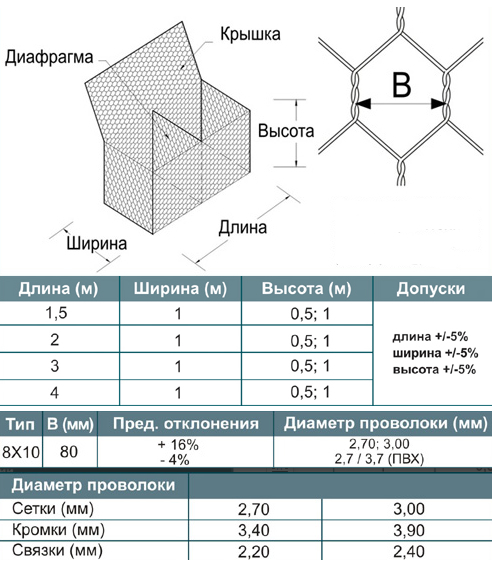

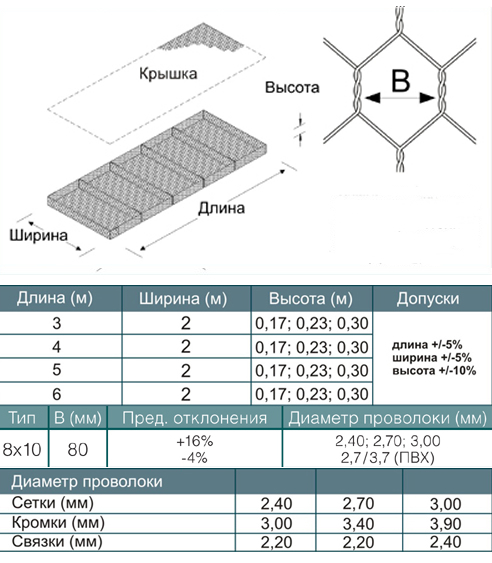

The mesh above is used for construction of following gabions:

CONSTRUCTION SPECIFICATION FOR WIRE MESH GABBION OR MATTRESS

Standard Size of Gabions Units

Gabion boxes made of heavy hexagonal wire nettings, subject to tolerance of 3 percent, more or less for size

Galvanized Gabions, Gabions 6 and 9 inches thick:

a) Length in multiples of individual compartments: 3 feet (0.9M~1M)

b) Width, minimum: 6 feet (1.8M)

c) Wire mesh woven into double or triple twisted hexagonal openings 2.25 inches by 3 Inches with tolerance of 0.25 inch.

d) Galvanized wire is required.

PVC coated Gabions, Gabions 12, 18, 24, and 36 inches thick:

a) Length in multiples of individual compartments: 3 feet (1.8M~2M).

b) Width minimum: 3 feet (0.9M)

c) Wire mesh: Woven into double or triple twisted hexagonal

openings 3 inches by 4.25 inches with tolerance of 0.25 inch.

d) PVC coating is required

Recommended size for the Gabion shall be 1m* 1m* 0.5m, 2m*1m*0.5m, 2m*1m*1m, 4m*1m*0.5m and 4m*1m*1m.

The size of the Gabion and Rock particle size relation as follow:

| Gabion basket or Mattress height in inches | Predominant rock size in inches | Minimum rock dimension in inches | Maximum Rock dimension in inches |

| Basket: 12, 18, 36 | 4 to 8 | 4 | 8 |

| Mattress: 6, 9, 12 | 3 to 5 | 3 | 5 |

At least 85 percent of the rock particles, by weight, shall be within the predominant rock size range.

The minimum technical specification for different types of wires to manufacture Gabion depend on the Gabion basket height as indicated below:

| A. Minimum Requirement for Gabion basket height 12, 18, or 36 inches | |||||

| Type of wire | Mesh size (inch) | Wire Diameter(Inch) | PVC coating(Inch) | Total Diameter(Inch) | Galvanized Coating oz/SF |

| Lacing Wire | 0.086 | 0.02 | 0.126 | 0.70 | |

| Mesh | 3X3 3X3 |

0.118 0.105 |

None 0.02 |

0.118 0.145 |

0.80 0.80 |

| Spiral Binder/slevage | 0.153 | 0.02 | 0.145 | 0.80 | |

| B. Minimum Requirement for Gabion basket height 6, 9, or 12 inches | |||||

| Lacing Wire | o.086 | 0.02 | 0.126 | 0.70 | |

| Mesh | 1.5 X3 | 0.086 | 0.02 | 0.120 | 0.70 |

| Spiral Binder/Slevage | 0.153 | 0.02 | 0.145 | 0.80 | |

Gabion Production Lines We Exported

Gabions machines export for USA Factory

Description:

Gabion machines, for processing salvage wire dia 4.2mm, mesh wire dia. 3.4mm.

Spiral coiling machine with 6 rods.

Net sheet straightening machine.

Stitching machine for 4 mtr. Length and 1 mtr. Length each.

Bundling machine.

Net sheet cutting machine.

Complete set of machinery export to Dubai

Description:

Complete set of machinery for making gabion mesh of size 80100 and 100120.

The mesh are for producing gabion boxes and mattresses.

Gabion Machine with Winding Machine to Algeria

Description:

Gabion Machine Model RK6080 2.4 ( Mesh size 6080, Width 2400 mm)

Winding machine: KS1200

Gabion Mesh, Box, Mattress Machine Exported to Russia

Description:

The machinery is an assemblied production line for producing of gabion wire netting, gabion boxes and mattresses. Including: spiral coiling machine, payoff netting straightening machine, mesh sheet cutting machine, twisting and winding machine, wire straightening and cutting machine for selvedge wire, netting border reinforcing device.

The machine can produce following box gabions and mattress nettings:

Матрацы

Quality Assurance

We supply technical specification with all the necessary supporting drawings, catalogue, brochures, past performance record and quality assurance certificate for the Gabion mesh Machines.

With rich experiences in this field, we can help with proposal preparation and minor modification to suit different Gabion wire mesh factory requirement, we can provide adequate justification.

Find the information interested?

Send a message and we will supply you with our most competitive price & delivery period at our earliest possible, with the complete technical datasheet of the offered machine products.