Containment transfer technology

Fast and secure transfer for large quantities

Containment

Economic solution

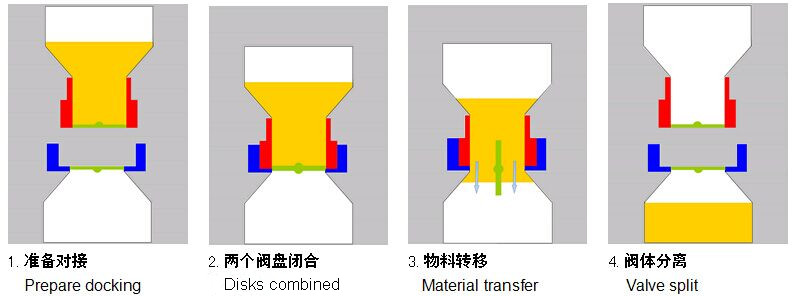

An Alpha Beta valve (Split butterfly valve) system is made up of an active and a passive split valve. The transfer of material from one container to another container is being carried on with seal condition, and the transfer process guarantees the sterile situation won't be destroyed or avoid being spread of the toxic materials in the container.

αβ valve -Conventional don't set isolation valve inlet and outlet, can't clean/sterilizer two discs exposed faces in place. People can wash and sterilization the exposed face by manual work to reach the normative requirement of material transfer.

Purpose of use

a. Protection of sterile product-Guarantee transfer process of sterile product avoiding being effected by outside microbe

b. Operator protection- Avoiding leakage of toxic materials during transfer process which is harmful for people

c. Eliminate loss of product yield during transfer

d. Effective dust control during transfer process

e. Reduce the potential of product cross-contamination

f. Save the cost on equipment