Platform Grating, is mostly made of heavy welded bar grating galvanised. Steel gratings serrated or grating panels combined with diamond pattern checker plate are safer and popular platform grating solutions.

We supply quality galvanized gratings to Europe, Canada, USA, Japan and many other countries.

Galvanized Steel Grating Panels

Grating, Hot Dip Galvanized, serrated to BS 4592, Size 19ft x 3ft

Rectangular pattern with hexagonal or square twisted cross bars.

- Size of bearing bars: 40mm x 5mm serrated.

- Spacing between bearing bars: 30mm, connected together

with 8mm hexagonal twisted rod every 100mm.

- Top surface of bearing bars shall be serrated.

- Grating panels shall be hot dip galvanized of minimum 460GM/M ^ 2.

- Pitch of cross bars: 50mm.

- Grating suitable for Max. SPAN 67" for 1/4" deflection under uniform working load of 6.6 KN/M ^ 2.

- The grating bar shall be closed end.

Common grating dimensions: 1" x 1/8" x 36" x 24"

Sheets of Galvanized Grating

Details:

Sheet dimensions:

2400mm load bar length

1200mm sheet width

Thickness: 32mm x 5 Flat bar

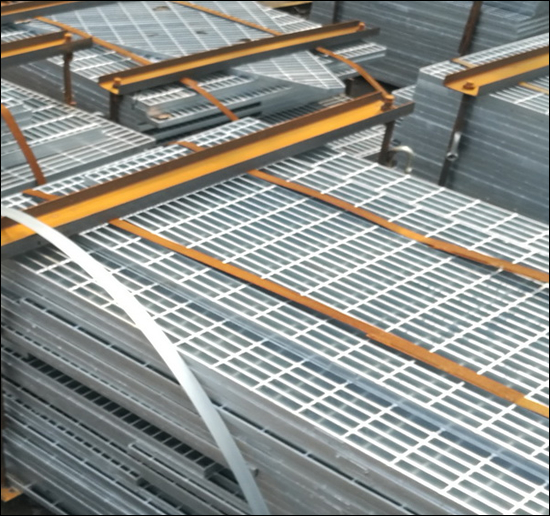

Galvanized Steel Platform Grating - Grid Safety Mats / Mattress

32x5 - 45kg per square meter, including fastening mat

Galvanized grates 30/5 type, heat galvanized

Grate step: 240800

Details:

Stair tread with non-slip reinforced nosing

Hot dip galvanized

Mesh: 3040

Bearing bar: 304 including fastening material

Stair Tread Drawing

Serrated Galvanized Grating

Serrated galvanised grating, with clamp / or clips, 6mm thk serrated bars, 25mm distance between serrated bars (internal), 8mm thk tie rods, 103mm distance between serration ties

Sheet length 6000mm, width 1000 mm x 35mm thickness grating

Galvanized Steel Grating for Construction

Exterior grating, maximum span 10'-6".

Suitable to varying lay-out in construction

Made in accordance with Standard Specifications for Construction:

- Grate dimensions

- Bar sizes and spacing

- Connection details

- Material type

- Coating

- Surface treatment

Materials.

All structural steel shall be Grade 36 or Grade 50. Mill reports for all steel used in the fabrication.

Grating shall use 2-1/4” (total depth with serrated edge) x 1/4” bearing bars, spaced at 1-3/8”. 3/8”

diameter crossbars shall be spaced at 4”. The grate width shall be 3 feet. Section lengths shall be

sized to end at the center of a 6x6 transverse beams, minimum 18’-9” lengths.

Surface treatment: serrated.

Finish: hot-dipped galvanized.

The connection hardware is hot-dipped galvanized.

Connection method : saddle clips and 3/8” diameter by 5” long lag bolts.

Construction. Place the galvanized steel grating full length of the span. Assure grating has full bearing on the steel plates

and transverse wood beams. The steel plate has holes to allow for saddle clip and lag bolt connections.

Removeable Galvanized grating on seating frame

Galvanized grating, removable, 800mm x 800mm x 50mm thk

on 76mm x 50mm x 6.5mm thk seating frame

1 inch x 3/16 inch Galvanized Steel Grating

Details:

Baring bars 1"x3/16"

Min.weight 9.0 lbs.per sq. ft fasten to inlet utilizing pipe sleeves and bolts

Grating panel size:

3’-4” x 4’-10”

2’-0” x 10’-0”

Drawing reference

Rectangular Opening Bar Grating, BS 4592 Hot Dipped Galvanised

Grating, open fabric, rectangular BS 4592, hot dip galvanized

Material: Steel

Grating size: 203 feet

Standard BS4592

Bearing bars 30mm x 5mm hot dip galvd

Rectangular pattern open steel fabric with hex/twisted square cross bars

Pitch of bearing bars 41mm, pitch of cross bars 50mm

Suitable for max. clear span of 1.5m with 6.0 kn. sqm. safe uni-formly distributed load. material

Compliance certificate & proto-type test (deflection, permanent deformation & collapse)

Coating: Heat Zinc coating

Heavy Duty Galvanized (Hot Dip) Steel Gratings

Size of the grating – 925mm x 1000mm

Square Cross Bar – 10 mm x 10mm

Bearing Plate – 120mm x 6mm thickness

Opening (pitch size) – 45mm x 45mm

2 sides with C Channels, size 100mm x 50mm x 5mm

Fabrication works includes notches/cut-outs

Galv: Hot dip galvanizing after fabrication

Welding specification as per BS EN: 4592

Galvanized Steel Bar Gratings

Sizes:

Resisting side 1310 mm

Mantled side 1695 mm

Open mesh 33x66mm

Side bar 302mm

frame bar on the end of the resisting sides 502mm.

Minting Gratings

Rectangular Hole Minting Gratings

Drawing: Symmetric Grating

Technical details:

Support bar: L2x303

Cross bar: 6mm twisted steel

Terminal frame: min. 38mm

Grating fabric: 38x71 mm rectangular

Supporting bar space: 38mm

Cross bar spacing: 71mm

Load: FV 1190KG/m2

Square Opening Minting Gratings

frame: 32x3

All support bar, cross bar and side frame are welded

DIN 24535 Industrial Standard

Supporting bar: 1062mm +0/-4

Cross bar: 490mm+0/-4

Fabric: 3030

Supporting bar material: 32x3

Cross bar material: 6x6 twisted steel

Grating lattice: 32mm height

Material: Steel, Galvanized

Load: 1025 kg/m2

DIN 50976 Hot Dip Galvanized Grating

Grating Panels 960612mm

Opening: 3030mm

Supporting rod: 2mm

Cross bar: 2mm

Grating height: 30mm

Material: Steel, Hot Dip Galvanized DIN 50976

Tolerance: RAL-GZ 638

L2x303 Serrated Grating

Opening: 3030mm

Grating height: 30mm

Cross bar: 5mm twisted steel

Material: S235 JR low carbon steel, Hot Dip Galvanized DIN 50976

Tolerance: +0/-4

303x6 Galv. Minting Grating

Grating hole: 3030mm

Support bar: 303mm

Cross bar: 6x6mm

Grating panel height: 30mm

Loading: 150kg/m2

Material: Carbon steel, Hot Dip Galvanized DIN 50976

Steel Gratings for Track Hopper Construction for Coal Handling Plant Package in Thermal Power Stations

Drawing reference

Thermal power stations need extensive coal handling and storage. Track Hoppers used for coal handling in power plants are constructed with reinforced cement concrete hopper with metal steel grating covers. All welds applied in grating construction are 6mm thick continuous fillet.

Size:

19502420mm

1950920mm

1438x2420mm

Plat Form Gratings - for Gas Production Facilities

Platform Gratings and Grating Clip

Material: Carbon steel

Hot Dip Galvanised

Platform grating refer attached drawing NO 9468-VP-SK-35-C-01-B01048/7-C6 rev3

Grating vendor to submit grating drawings for approval before fabrication

Gratings to be hot dip galvanised in accordance with ASTM A 123 or A153

Befor galvanizing maerial shall be fully fabricated, free from all flashes or burrs, with smooth edges, and with all welding complete

Gratings to be 32 * 5 serrated bearing bars & binding bars on 30 NOM centers, c/2 square twisted bars on 100 center

| DEscriptION | MATERIAL | SIZE |

| PIPE SUPPORT CLIP | SA516-70 | 221 x 196 x 10 THK. |

| PIPE SUPPORT CLIP | SA516-70 | 284 x 303 x IO THK. |

| PIPE SUPPORT CLIP | SA516-70 | 158 x 467 x ID THK. |

| PIPE SUPPORT CLIP | SA516-70 | 158 x 467 x 1D_TRK. |

| PIPE SUPPORT PAD | SA516-70 | 299 x 110 x 10 THK. |

| PIPE SUPPORT PAD | SA516-70 | 403 x.110 x 10 THK. |

| PIPE SUPPORT PAD | SA516-70 | 467 x 110 x 10 THK |

| PIPE SUPPORT PAD | SA516-70 | 467 x 110 x 10 THK |

| LADDER CLIP | SA516-70 | 209 x 1D0 x 10 THK. |

| LADDER CLIP PAD | SA516-70 | 200 x 100 x 10 THK. |

| LADDER CLIP | SA516-70 | 95 x 100 x 10 THK_ |

| LADDER CLIP | SA516-70 | 146 x 100 x 10 THK |

| LADDER CLIP | SA516-70 | 100 x 100 x 10 THK. |

| STFFNER CLIP | SA516-70 | 131 x 100 x 10 THK. |

| PIPE SUPPORT CLIP | SA516-70 | 100 x 100 x 10 THK. |

| PIPE SUPPORT PAD | SA516-70 | 200 x 90 x 10 THK. |

FOURTH PLATFORM

FIFTH PLATFORM

Platform Ladder Grating and Pipe Clip