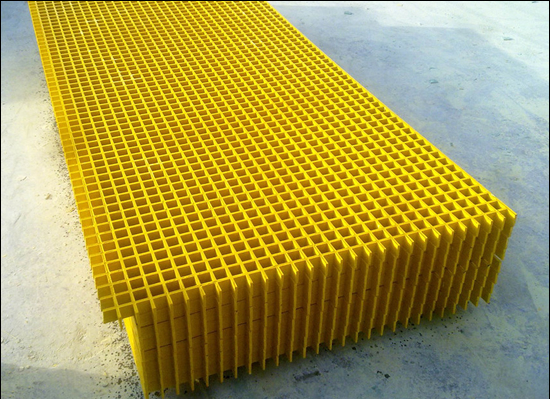

Pultrusion glass fiber grating is made by a continuous molded process in which glass roving and matting are pulled through a vinylester or polyester resin bath. We supply fiberglass grating pultruded in standard panels 4 x 4, 4 x 10, 4 x 12, 4 x 20, 3 x 10 and 3 x 20 in feet.

Layers of resin and fiberglass strands molded bar grating with excellent impact resistance provides better traction than metal bar grating and costs less. Narrow-Opening Fiberglass Bar Grating is used to prevent items from falling through and this grating make it easier for carts to roll across.

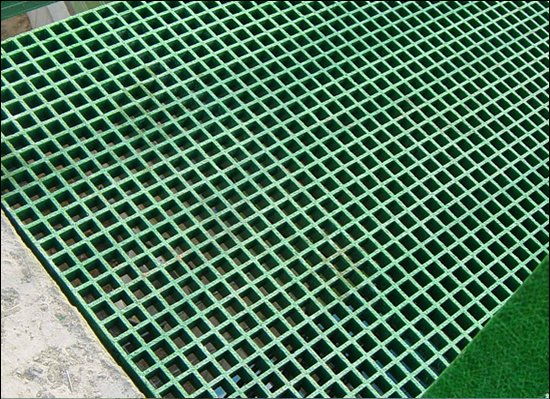

Reinforced fiberglass plastic (RFP) composite grating

Fiberglass grating provides excellent strength per weight ratio, and is ideal in high corrosive situations.

The molded and pultrusion grating styles are available with anti-skid surface, fire retardant corrosion resistant, U.V. protected, non-conductive and are lightweight.

We offer fiberglass structural shapes produced in more than 100 configurations. Fiberglass structural gratings and mats are widely used in industrial construction, maintenance, as components for industrial equipment, and commercial products.