Benefits of Welded Grating:

By pressing and welding to form a homogenous unit of all intersection points, high shear forces can be absorbed. Depending on static or dynamic loading, heavy-duty gratings can be provided for many applications depending on the clear span.

Material: Carbon Steel,Stainless Steel

Surface: Smooth,Serrated

Finish: Mill Finish, Black Primer, H.D. Galvanized

Material Standard:

Mild steel - We utilize a high quality mild steel for load bearing bars, which exceeds the strength of ASTM A36, BS4360 Grade 43A and JIS G3101 SS400, KSD3505 SB41. This is particularly beneficial where a floor is subjected to wheel loads, as deflection becomes a subordinate consideration to the ability of the load bearing bar to withstand high stress.

Stainless Steel Floor can also be manufactured from stainless steel. The normal grade used are 304 and 316, but other grades can be considered upon request.

Manufacturing Standards

Qindelin Gratings are designed and manufacture in accordance with relevant international standards. The figures found in the Load and Deflection tables are calculated in compliance to national standard, while the manufacture conforms to the requirement of international standard.

Common Sizes:

Pitch of Bearing Bar

A center distance between the two bearing bars adjacent to each other.

*Common pitch : 30mm & 40mm

Other : 12.5mm, 15mm, 25mm, 60mm

Pitch of Cross Bar

A center distance between the two cross bars adjacent to each other.

*Standard pitch : 50mm & 100mm.

NOTE

Difference spacing of bearing bar & Cross bar can also be manufacture upon request.

Uses:

Electro-Forged Steel Grating can be used as industrial trucks, stair treads and various floorings.

Heavy Welded Bar Grating

Galvanized steel welded grating panels

Width 24", Span 60"

1/4" x 1" Bearing Bars, 1-3/16" center to center spacing.

Heavy welded cross bars on 4" centers

Smooth surface, Load Banded with equal gauge stubs welded ends.

Welded Steel Bar Grating Supplied with Chequered Plate Steel

Flat Bar Grating welded, hot dipped galvanized finish

Material: Carbon Steel with galvanized finishing

Panel Width x length:Im x 6m

Details:

Non-serrated/smooth bar grating.

Bearing bar size: 1-1/4"x 3/16"

The bearing bars 19/16's(1-3/16)inches on center

Cross bars spaced at 4 inches on center.

Types of bearing bar: Flat bars; made from steel strip or slit sheet, or rolled.

Finishing:Hot Dip Galvanizing, zinc coating minimum average coated per Standards AS1650,BS729 and ASTM A123.

Grating safety guard plate: Checker plate steel, hot dipped galv.

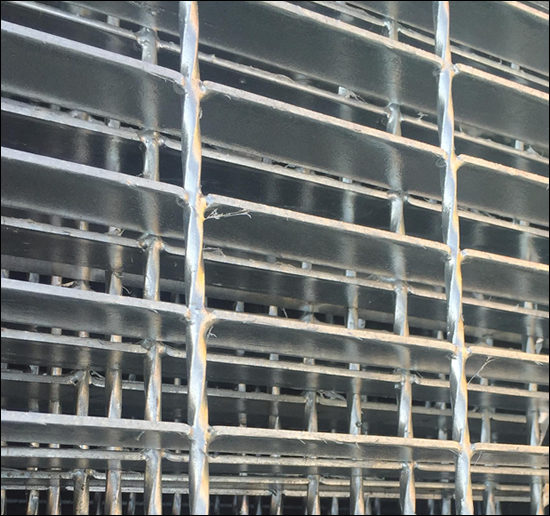

Press Welded Steel Grating - for industrial platforms

Presswelded steel gratings, not galvanized, natural steel colour

The bearing bars placed edgeways connected with twisted cover rods, embedded with a force of 1000KN, welded at 2500KVA.

Mesh size 34x76mm

Bearing bar 303mm

Size of panel 58001000mm

Material S235 Low carbon steel

Finish: Zinc coated

framed

Materials also available:

Steel, zinc coated finish

Aluminum, anodized

Stainless steel, etched

Bearing bar sizes also available:

207mm, 301mm, 34x3mm, 41x4mm

Anti-skid protection: Notched bearing bar

Welded metal Bar Grating - for Oil and Gas Industry

Industrial grating, welded, details:

Sheet size 6100 (6000) x 1000mm

Cell size 34x38 / 303 mm

Material: Steel S235

Finish:Corrosion-resistant, hot-dip galvanized by EN ISO 1461: 2009

No borders

Dimensions in accordance with RAL GZ 638

Standard: DIN 24537-1:2006-04, DIN 24531-1

Technical Terms Applied for Welded Bar Gratings

U = safe uniform load, psf

C= safe concentrated load, pfw

D = deflection, inches

E =modulus of elasticity,29,000,000 psi

F =fiber stress,18,000 psi

Material: ASTM A-569 standard

Defiection: Spans and loads to the right of the bold line exceed 1/4"deflection for uniform load of 100 psf which provides safe pedestrian comfort. These can be exceeded for other types of loads with engineer's approval.

Serratet Bars: For serrated grating, the depth of grating required for a specified load is 1/4"deeper than standard.

General: Loads and deflections are theoretical and based on static loading.