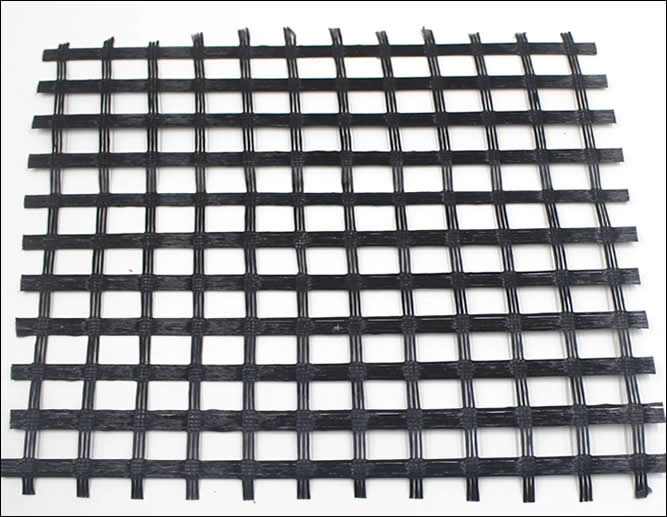

Biaxial geogrids are designed to spread loads over a large area, reducing excavation needs and providing an economical design. Their ribs interlock with the surrounding soil particles, increasing bearing capacity and reducing time and cost associated with placement and construction.

Biaxial geogrids ribs thickness and unit weight

Biaxial geogrids rib thickness (1mm) , 150g/m²

Biaxial geogrids rib thickness (1.5mm) , 230g/m²

Biaxial geogrids rib thicknesses (2mm) , 300g/m²

Biaxial geogrids rib thicknesses (2.5mm), 350g/m²

(The above is the estimated value, the tolerance is 1-2g/sqm)

Application

Biaxial geogrid provides a long-term resistance to deformation and enhances the bearing capacity of road and ground foundations, extending their service life, it is used to:

1, prevent caving in or cracks in the road or ground surfaces and keeps them looking neat and tidy.

2, stop culverts from cracking.

3, improve soil slope stability and prevents soil erosion.

4, reduce the required thickness of bedding layers, saving costs.

5, support slope vegetation mesh mats to green the environment.

6. replac metal mesh for coal mine shafts.

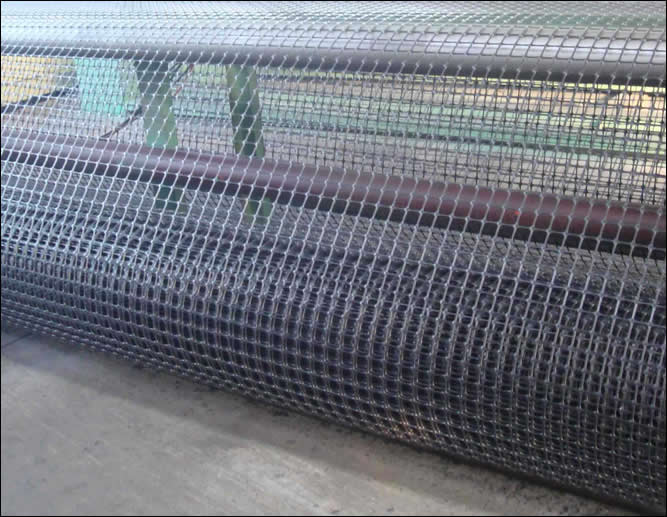

PP biaxial geogrid within road subbase project to increase stablization:

Configuration: Biaxial

Raw Material: PP polymer

Color: Black or White

Tensile Strength at 2% Strain (MD&CD), kN/m: 12.5 (Min.)

Tensile Strength at 5% Strain (MD&CD), kN/m: 24 (Min.)

Ultimate Tensile Strength (MD&CD), kN/m: 30 (Min.)

Elongation at Ultimate Tensile Strength (MD&CD), %: 8 (Max.)

Mass per Unit Area, g/m^2: 200 (Min.)

Plastic Extruded Biaxial Geogrid

Material: Polypropylene extruded pvc

Construction: Bi-axial

Grid opening: 4040mm, tolerance 4mm more or less

Color:Carbon black