Introduction of Small Scale Potato Chips Line

Fried potato chips are a kind of leisure food which is popular all over the world and deeply welcomed by consumers. It remains the special delicious flavor of roasted potato on one respect and has the characters of rich nutrition and delicious. The potato chips production line that we supply has advantages like low one-time investment, low energy consumption, multi-functions, small volume, high profits, easy to use and maintain, etc. which is an excellent choice for you to processing potato chips.

Features of Small Scale Potato Chips Line

1. Every machine is made of high quality stainless steel, up to health standard, easy to clean.

2. High work efficiency, save labor and energy.

3. Low oil consumption, high degree automation, creates more benefits.

4. Advanced technology, long service life.

5. Economical and practical, superior quality and competitive price.

6. Low cost. Suitable for low scale potato chips production

7. 30kg/h, 60kg/h, 150kg/h. Three capacity models for your choice.

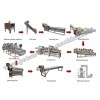

The Functions of Each Potato Chips Machine

❤ Potato washing & peeling machine: used to clean and peel the skin of potatoes, energy conserving and high efficiency.

❤ Potato cutting machine: slice the potatoes into slices and bar shape, the thickness can be adjusted according to your preference.

❤ Chips blanching machine: this is used for washing the potato chips, making them look more attractive.

❤ De-watering machine: with centrifugal force, saving the time of frying and make the chips more delicious.

❤ Chips Frying machine: adopt water & oil mixture frying machine, after the operation is finished, you just need to release the water, at the same time the residue will flow outside together with the water, greatly increasing the oil's using recycle.

❤ De-oiling machine: reduce the oil content of potato chips, make preparation for flavoring.

❤ Flavoring machine: adopt spray method, seasoning the potato chips evenly, and the potato chips are not easy to break.

❤ Potato chips packing machine: inflate the nitrogen into bags while package potato chips. Could finish inflation, packaging and printing one time

The Parameters of 30kgh Small Scale Potato Chips Line

| No. | Item Name | Power | Weight | Size |

| 1 | IEP10 Washing and peeling machine | 0.75kw/220v | 60kg | 690*430*860mm |

| 2 | IPS400 Potato cutting machine | 0.75kw/220v | 60kg | 650*510*700mm |

| 3 | PT1000 Blanching machine | 15kw/380v | 50kg | 1310*650*700mm |

| 4 | TS500 De-watering machine | 0.75kw/380v | 400kg | 940*560*830mm |

| 5 | DYZ1000 Frying machine | 21kw/380v | 120kg | 1380*620*950mm |

| 6 | TY500 De-oiling machine | 0.75kw/380v | 400kg | 940*560*830mm |

| 7 | BL800 Flavoring machine | 0.75kw/220v | 90kg | 1000*800*1380mm |

| 8 | DZ400-2SVacuum packing machine | 1kw/380v | 180kg | 1050*650*855mm |