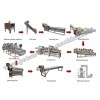

Automatic Potato Chips Line Introduction

Automatic potato chips processing line is developed by our company based on the advanced technology in combination with the food production enterprise features. This processing line avoids large investment high charge. Meanwhile it has the following features: high automatic, high efficiency and energy -saving. The processing capacities are 100-150kg/h, 200-260kg/h and 350-400kg/h.

| Model | Capacity | Power Consumption |

| IPC-100 | 100-150kg/h | 155.8Kw.h |

| IPC-200 | 200-260kg/h | 209.7Kw.h |

| IPC-350 | 350-400kg/h | 270.4Kw.h |

Advantages of Automatic Potato Chips Line

1. High efficiency: the whole production line is easy to operate with high productivity.

2. Reliable performance: the potato chips and crisps have good shape with smooth surface and uniform thickness. Besides, the thickness could be adjusted according to your requirements.

3. Multifunctional: potatoes, sweet potatoes, carrots, cassava and other root-stem vegetables could be processed as the raw materials.

4. Safe: all the machines are made by stainless steel which accords with the healthy standards well.

Brief Description of Potato Chips Machines

☞ Potato elevator: used to transfer the fresh potatoes into the cleaning and peeling machine in large quantity. This machine is optional for some chips making factory.

☞ Cleaning and peeling machine: used to wash the fresh potatoes and peel the skin automatically without damage.

☞ Potato Cutting machine: cut the potatoes into chips, sticks and wave chips, just change different knives. The thickness of the chips or sticks is adjustable.

☞ Chips Blanching machine: used to prepare for chips frying, it can make the color, taste better and make the chips crispier.

☞ De-watering machine: used to reduce the water contained in the chips, thus it will be easier to be fried.

☞ Frying machine: For the potato chips needed to be totally fried to make it crisper, if produce frozen French fries, only need to be half fried.

☞ De-oiling machine: totally remove the oil in the products.

☞ Flavoring machine: it is to mix the flavor to the surface of the chips to get different taste chips. Cover more consumers.

☞ Chips packing machine: used to pack the final product. Our fully automatic packing machine can feed, elevate, weigh and pack the potato chips automatically.

100-150kg/h Automatic Potato Chips Line Technical Data

| No. | Name | Power/Voltage | Dimension |

| 1 | Potato Elevator | 0.55kw/380V/50Hz | 2535*900*2150mm |

| 2 | Washing and Peeling Machine | 2.75kw/380V/50Hz | 3050*800*1600mm |

| 3 | Potato Picking Line | 0.55kw/380V/50Hz | 3700*1040*940mm |

| 4 | Elevator | 0.55kw/380V/50Hz | 1700*700*1740mm |

| 5 | Potato Cutting Machine | 1.5kw/380V/50Hz | 670*510*1400mm |

| 6 | Bubble Cleaning Line | 1.87kw/380V/50Hz | 3490*1450*1400mm |

| 7 | Blanching Line | 40.5kw/380V/50Hz | 5100*1070*1240mm |

| 8 | Rinsing Line | 1.87kw/380V/50Hz | 3490*1450*1400mm |

| 9 | Air-cooled De-watering Machine | 6kw/380V/50Hz | 4100*850*1840mm |

| 10 | Electrical Frying Line | 125kw/380V/50Hz | 5600*1700*2250mm |

| 11 | De-oiling Line | 6kw/380V/50Hz | 4100*850*1880mm |

| 12 | Flavoring Line | 1.12kw/380V/50Hz | 3240*850*2200mm |

| 13 | Picking Line | 0.55kw/380V/50Hz | 3560*700*1255mm |

| 14 | Packing Machine | 6kw/380V/50Hz | / |