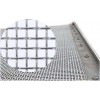

Water Well Screens are designed for construction of well depths of 100 m, 200 m, 350 m & 600 m. Custom deep wells available upon request. It is manufactured using our unique digital controlled machinery in which a continuous length of profile wire of a triangular section is fusion welded onto support rods to form a pipe screen.

Uses: Stainless steel water well screen can use with the deep well pump, water diving pump, also may use in the water-treating equipment, the environmental protection, the sea water transforms into the industrial water and life use water desalination treatment, running water treatment, water softening treatment, the petroleum industry as the petroleum product terminal filters and the chemical acid, the alkali liquid filters, the ethyl alcohol and the organic solution recycling filters and so on.

General Technical Information

Profile wire or wedge wire material:

Width(mm):1.5,1.8,2.3,3.0,3.3,3.7,4.0,4.5

Height(mm): 1.5,2.2,2.5,2.7,3.0,3.6,4.0,4.3,4.5,4.70,5.5

Support rods:

Width(mm): 2.0,2.3,2.5,3.0,3.3,3.7,4.0,4.5.

Height(mm): 1.5,2.2,2.5,2.7,3.0,3.6,4.0,4.5,4.7,5.5.

Round rods : diameter from 2.50mm to 6.0mm. 1.8,2.3,3.0,3.3,3.7,4.0,4.5.

Height(mm): 1.5,2.2,2.5,2.7,3.0,3.6,4.0,4.3,4.5,4.70,5.5.

End Connection: By welding or by threaded male/female coupling.

Slot Size: 0.05,0.08,0.10,0.15,0.20,0.25,0.30,1.0,2.0,5.0... 45mm also achieved upon request.