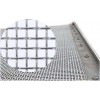

Features of Crimped Steel Mesh Panels:

With more open area;

Lasts Longer;

The design outwears profile wire by up to ten times, and needs to be turned only 1/5 as often as profile wire;

Less Work - Less Downtime;

The long lasting screen panel mounts on a durable stainless steel frame. There is simply less work with a mesh sieve screen.

More Choices of Opening Size. Custom designs available with coming samples or drawings.

Crimped wire mesh is woven using wire crimped prior to weaving. The crimps are made at the points the shute and warp wires intersect which secures the wire, thereby stabilizing the wire cloth and preventing the wire from moving.

The crimped mesh are specially designed for extremely rugged operations for grading, sizing, processing and supporting heavy abrasive materials such as ores, crushed stones, sand ,gravel, metallic & non metallic minerals, coal slag and various solid and powder formed organic and inorganic chemicals.

Size & Configurations

a. Wire diameter typically range from 1.5mm to 5.0mm

b. Hole size up to 100mm

c. Weave type include plain crimped, single & double intermediate, lock crimped, flat top and slot hole crimped.