Profile wire wrapped water well screen

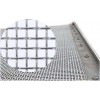

V wire wrapped slot screen is manufactured by wrapping a shaped wire around an internal array of longitudinal rods.

The wire and rod, generally made from carbon or stainless steel are joined by resistance welding. Screen sections are usually twenty feet long.

Commonly referred to as continuous slot or wire wrap screen, this product was originally developed to overcome problems associated with cable tool wells drilled in fine grained.

Cliclean offers steel pipes for water well conductor pipe, oil well screen surface casing and protection. The well screen casings can be produced according to three standards: Chinese standard, German Standard and American Standard.

303mm Austenitic Stainless Steel 304 Stainless Steel Water Well Conductor Pipe

5.8 meter length with male threads from both ends and female coupling (minimum wall thickness should be 0.375”). The quality of the conductor should meet international standards like API, ASTM, DIN or equivalent.

219mm Austenitic Stainless Steel 304 Water Well Casing Pipe

5.8 meter length with male threads from both ends and female coupling. The minimum thickness of the pipe should be 0.296”. The quality of casing pipe should meet international standards like API, ASTM, DIN or equivalent. A certificate of standard should be submitted.

219mm Austenitic Stainless Steel 304 Free Flow Continuous slot pipe based water well screens

5.8 meter length fully compatible with casing pipe (line number 2) and with male threads from both ends and female coupling. The slot size (in thousandths of an inch) screen should be 40. The quality of screen should meet international

standards like API, ASTM, DIN or equivalent

Advantages:

A continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone (the aquifer)

A "V" shaped profile wire which avoids clogging and ensures an uninterrupted flow.

A uniform and efficient well development due to the continuous slot opening.