Designed to ensure a straight, smooth run with an exceptionally flat surface, these belts enhance the efficiency of product movement across a wide array of industries. Constructed with durable eye-link modules, plate links, and cross rods, they form a flexible yet robust structure, ideal for heavy-load applications.

Material:

The material options for Eye link Conveyor Belts can be expanded to include:

- 304 Stainless Steel (T304SS): Known for its corrosion resistance and durability, making it suitable for a variety of food processing and industrial applications.

- 316 Stainless Steel (T316SS): Offers enhanced corrosion resistance compared to 304 stainless steel, ideal for more corrosive environments such as those involving chemicals or saline.

- Carbon Steel: Provides high strength and is cost-effective, suitable for applications where corrosion resistance is not the primary concern.

- Other Materials: Available upon request to meet specific requirements or application needs, ensuring flexibility and adaptability for various industrial uses.

These material options further enhance the adaptability and utility of Eye link Conveyor Belts, allowing them to cater to a wider range of applications and environments.

Durability Meets Heavy-Duty Performance

Crafted with eye-link modules, plate links, and cross rods, Qijie’s belts offer a flexible, hinge-like structure. This design evenly distributes load and ensures stability and longevity, making these belts perfect for heavy-load applications. They merge a stable carrying surface with the inherent strength of their construction.

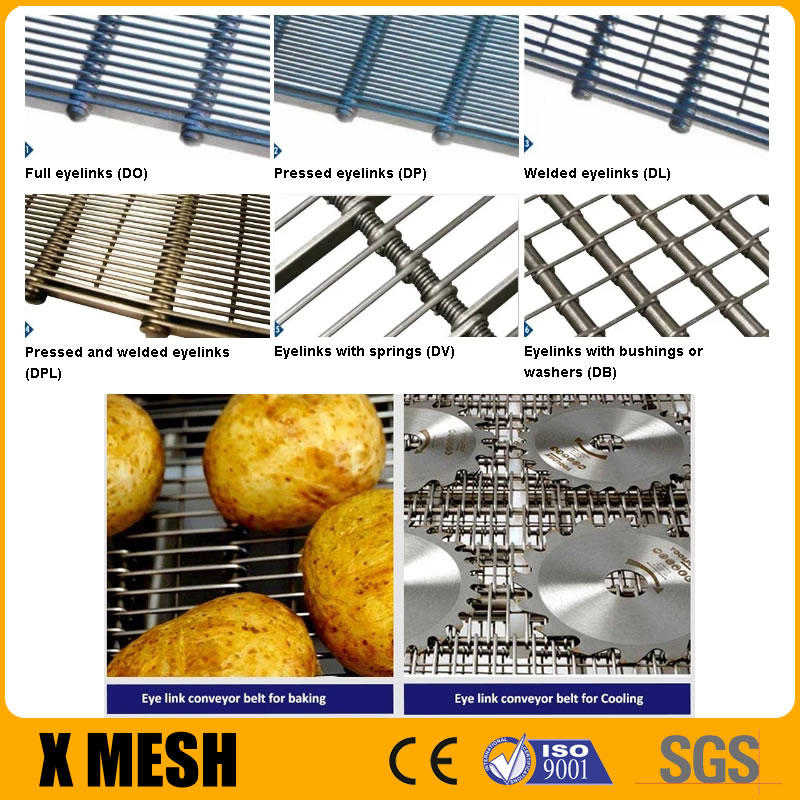

Eye link Designs

Qijie’s Eye link Conveyor Belts offer customization, catering to a broad spectrum of industrial requirements. The belts are available in several distinct styles – full eyelink, eyelink with spring, eyelink with rings, and eyelink with underwelded wire – each tailored for specific applications. The full eyelink style, notable for its flow-through properties, is particularly effective in food processing for small product conveyance due to its flat conveying surface and ease of cleaning.

Specialized Eye link Variations for Enhanced Functionality

- Simplified Overview of Eye link Conveyor Belt Variations

- Full Eye links: Belts with closely aligned links for a flat surface, ideal for even conveyance.

- Pressed Eye links: Belts with flattened links for very small gaps, great for tiny or fine products.

- Welded Eye links: Belts with links welded to wires, forming flexible modules, easy to clean and suitable for various product sizes.

- Pressed and Welded Eye links: Sturdy belts with small openings, perfect for stable conveying with minimal gaps.

- Eye links with Springs: Belts with springs for stability in temperature changes, ensuring effective cleaning.

- Eye links with Bushings or Washers: Belts designed with gaps for better airflow around products, enhancing process efficiency.

- Eye link Belt with Welded Edge: Belts with reinforced edges for a polished look and extra support.

- Eye link Belt with Reinforcing Plates: Strong belts with metal plates at edges, ideal for intensive use.

- Eye link Belt with Chain Edge: Belts with a chain edge for alternative driving and stable tracking.

- Eye link Belt with Side Guards: Belts with customizable side barriers to keep products in place, good for organized product lines.