Features And Advantages Of The Ladder Conveyor Belt

Ladder Conveyor Belt combines reliability, adaptability, and ease of use, making it a highly effective solution for a variety of industrial applications.The Ladder Conveyor Belt, a popular choice in the baking industry and various other sectors, offers numerous features and advantages that enhance its performance and usability:

- Reliable Movement: Equipped with a positive sprocket drive for consistent, trackless operation.

- Adaptable Design: Suitable for both straight-running and radial applications, with S-hooks for straight applications, curved belt options for fixed radius turns, and a tapered rod pitch for radial applications (90 and 180 degrees).

- Uniform Carrying Surface: The belt’s flat surface is gentle on products, ensuring safe handling.

- Durability: High tensile strength rods add durability and reduce the risk of distortion, minimizing downtime.Its simple construction allows for easy assembly and disassembly.Designed for efficient cleaning, maintaining high hygiene standards.Minimal upkeep required, enhancing cost-effectiveness.

- Mesh Overlay Option: Available for enhanced transportation of smaller items.

- Efficient Transportation: The belt’s flat and smooth surface ensures safe and efficient transportation of goods.

- Gentle Handling: Ideal for carefully handling products.

- Smooth Movement: Facilitates easy movement, particularly around radial bends.

- Optional U-Bar Filler Rods: Available for added product support.

- Simple Construction: Straightforward design for easy handling and maintenance.

Application Of The Ladder Conveyor Belt

The Ladder Conveyor Belt is known for its adaptability and is used in a wide range of applications across multiple industries:

- Versatility: It fits into various conveyor systems due to its adaptable design, making it suitable for numerous industrial processes.

- Food Industry Applications: The belt is particularly effective in the food industry, excelling in processes such as cooling, baking, frying, and grilling, with a specific emphasis on bread and pastry production.

- Filtering Systems: It plays a crucial role in various filtering installations.

- Washing and Drying: The belt is ideal for washing and drying processes in different sectors.

- Broad Range of Functions: It is used for a variety of tasks including transportation, cooking, heating, drying, cooling, drainage, freezing, washing, inspection, packaging, as well as handling operations like elevating, de-elevating, turning, and filling.

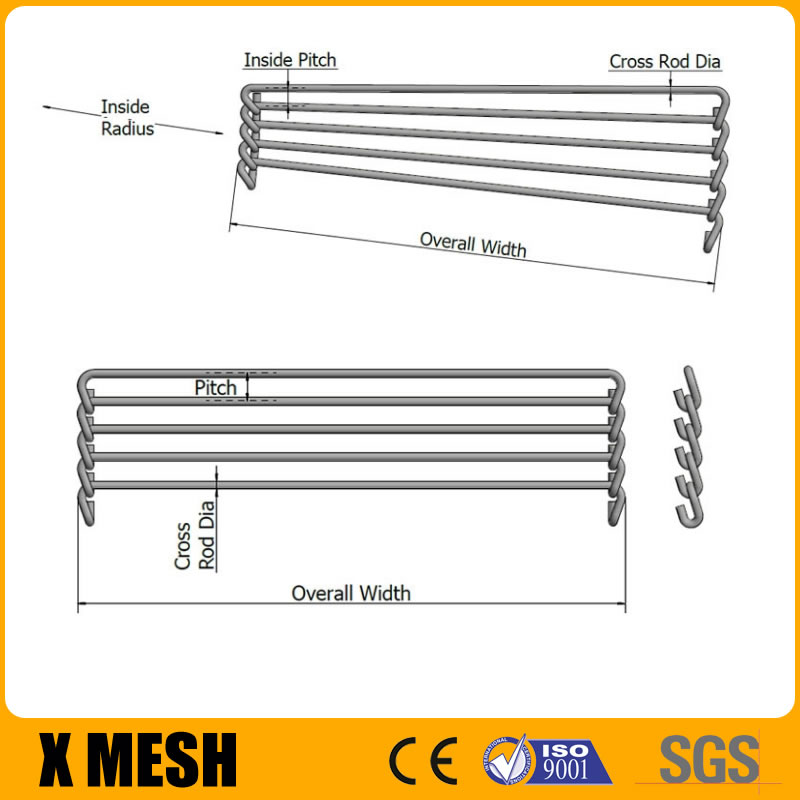

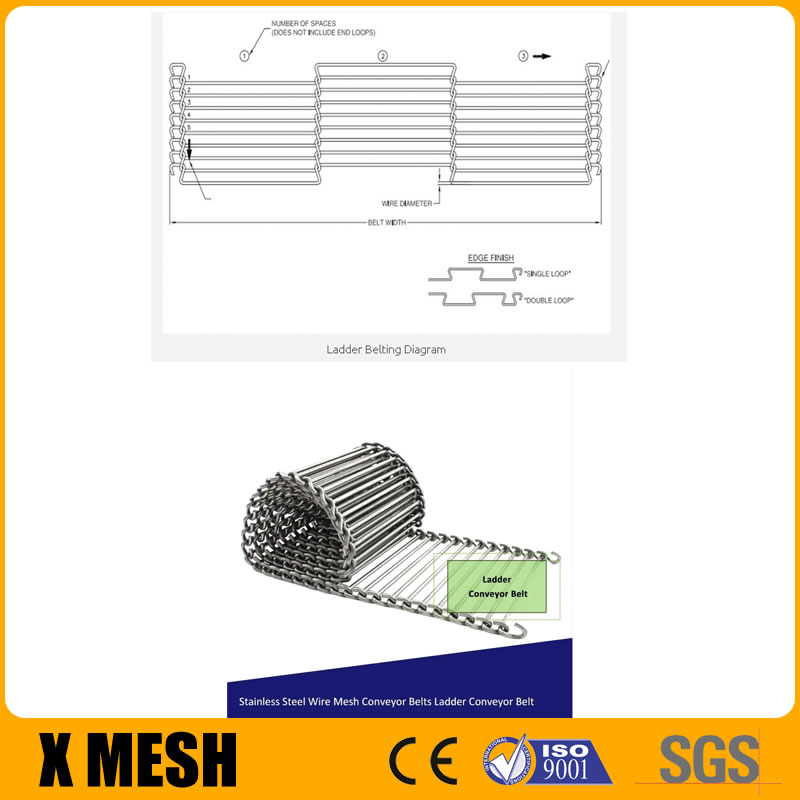

Ladder Conveyor Belt Structure Type

The Ladder Conveyor Belt is designed to offer stable and secure conveyance in various industrial settings, characterized by its unique structure and variety of link types.

Structure and Security:The belt is constructed with cross rods connected by S-shaped hooks, chain links, and U-shaped links. Its integrity is enhanced with rings welded to the cross rods, increasing the durability and stability of the conveyor belts.

Type of Ladder Conveyor Belt:

- Ladder Belt with S-Shaped Hooks:

Application Flexibility: Suitable for both straight and curved paths.

Curvature Options: Can be adapted as curved belts with a fixed inside radius.

Directional Variability: Available in right-hand (clockwise) and left-hand (anti-clockwise) arrangements.

Standard Angles: Designed for conveyor angles of either 90° or 180°. - Ladder Belt with U-Shaped links:

Versatile Use: Efficient in both straight and curved applications.

Directional Options: Comes in right-hand (clockwise) and left-hand (anti-clockwise) configurations.

Conveyor Angle Compatibility: Suitable for standard angles of 90° and 180°. - Ladder Belt with Chain links:

Specific Application: Tailored exclusively for straight-running applications.

Each type of the Ladder Conveyor Belt is crafted to meet specific operational needs, showcasing the flexibility and efficiency of conveyor technology. These belts exemplify the capability of conveyor systems to adapt to a wide range of industrial processes and material handling requirements.