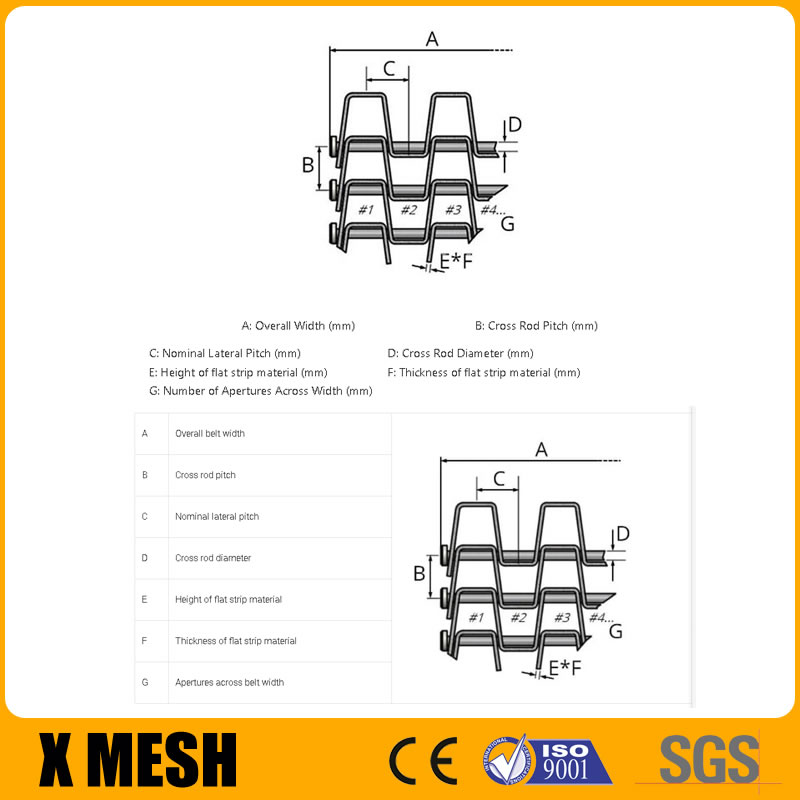

Design:

- Design Efficiency and Strength

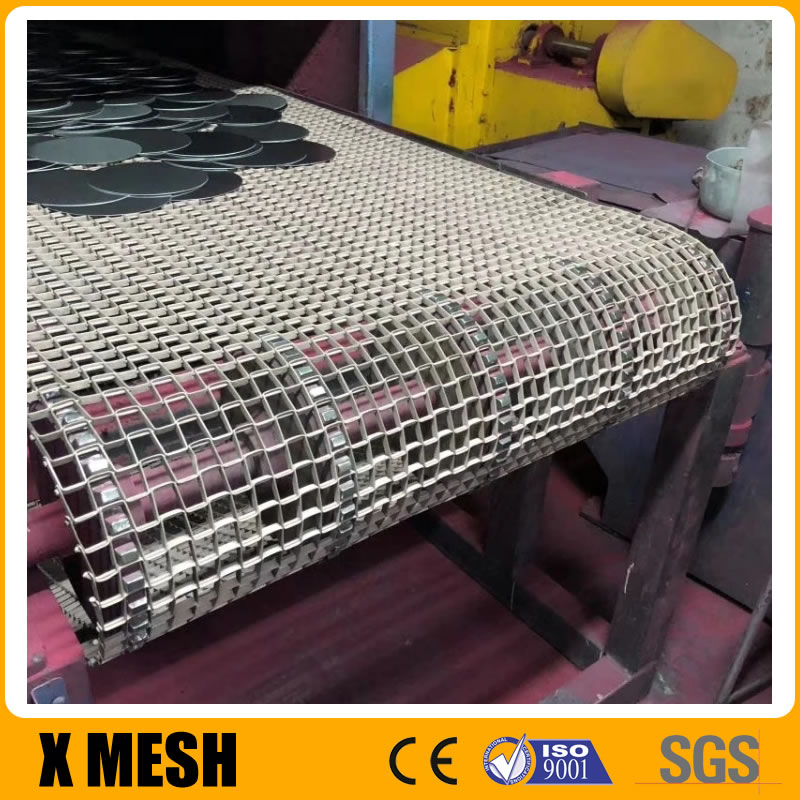

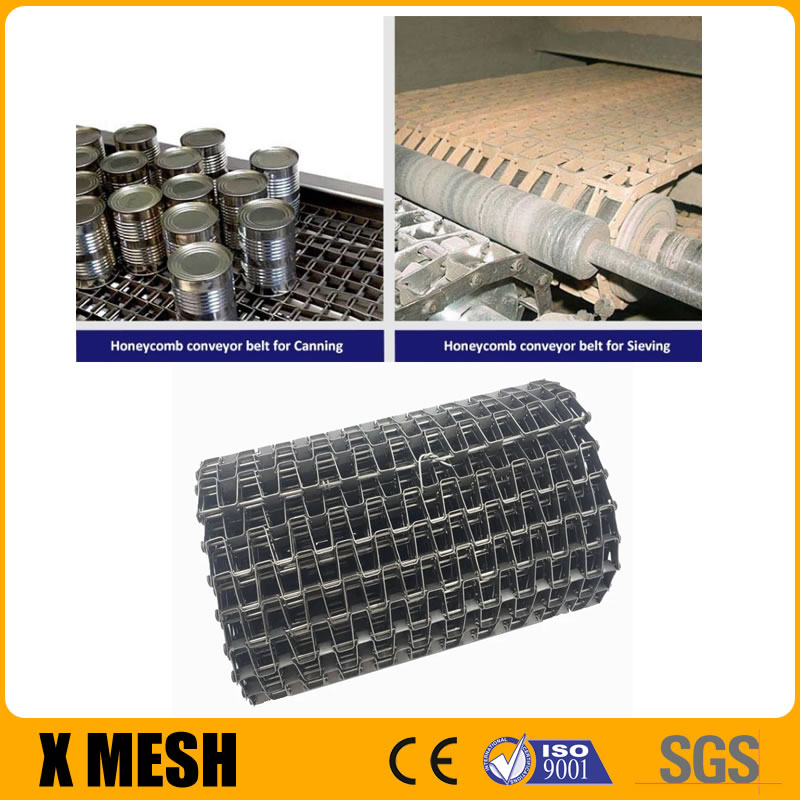

Honeycomb conveyor belts are ingeniously crafted for lightweight yet strong performance, with a high strength-to-weight ratio. This design allows them to handle significant loads while being easy to operate and maintain. - Customization and Versatility

These belts are adaptable, available in various sizes and with optional additions like side plates or flights, catering to a range of industrial needs. Their large open area is ideal for processes needing quick drainage and air circulation, making them suitable for industries involving drying, cooling, or washing. - Functionality and Application

Designed for easy joining and maintenance, these belts can be driven by customizable stainless steel or nylon sprockets, enhancing their versatility in different industrial settings. This adaptability makes them ideal for a variety of applications, including food processing, s, and packaging.

Benefits:

- Long-lasting, with double the lifespan of many similar belts.

- Easy installation without the need for special tools.

- Excellent belt tracking due to positive drive.

- Up to 81% open area for efficient flow-through.

- Available in widths up to 150 inches.

- Strong edge design reduces snagging.

- Flat surface and open mesh design for easy cleaning and maintenance.

- Edges with welded rings or clinched edges for stability.

Materials

- Honeycomb conveyor belts, known for their versatility, are available in a variety of materials including high carbon steel, galvanized steel, and both 304 and 316 stainless steel. This range of materials makes them adaptable to diverse industrial uses. High carbon steel belts are prized for their strength and are ideal for applications like casting where robustness is essential.

- Galvanized steel, treated with a protective layer of zinc, is suitable for environments prone to moisture or corrosive elements, making it a good choice for drainage applications. The 304 and 316 grades of stainless steel offer excellent corrosion resistance and durability. These stainless steels are especially beneficial in food-related applications, such as baking and food packaging, due to their non-reactive nature with food substances.

- In particular, food-grade stainless steel, like SUS304 and SUS316, is specifically used for food conveyors, ensuring safety and compliance with food industry standards. The selection of the appropriate material for a honeycomb conveyor belt is crucial and depends on the specific requirements of the application, including factors like temperature resistance, corrosion resistance, and strength.