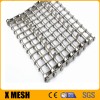

Materials

The Flat Flex Conveyor Belt is made from high-quality materials, primarily stainless steel, known for its durability, strength, and corrosion resistance. It also offers other alloys to meet specific requirements, including carbon steel for affordability and strength, galvanized steel for enhanced corrosion resistance, and specialized alloys for extreme temperatures or chemical exposure. The material choice varies according to the application; for example, food processing uses non-toxic, food-grade stainless steel for safety, while heat treatment processes utilize heat-resistant alloys.

Applications Of The Flat Flex Conveyor Belt

- Food Processing

Baking, Frying, and Cooling: Ideal for different stages in food preparation, ensuring hygiene and efficiency.

Freezing: Suitable for cold environments, maintaining performance under low temperatures. - Electronics Industry

Component Handling: Used for delicate handling and precise positioning of electronic components. - Packaging Industry

Product Transport: Facilitates smooth transport and handling of various packaged goods. - Automotive Sector

Assembly Lines: Integral in automotive assembly and parts handling, aiding in efficient production processes. - metalworking

Heavy-Duty Use: Endures high loads and abrasive conditions, perfect for metalworking applications. - Industry

Medication Handling: Plays a critical role in the processing and handling of medications, where cleanliness and precision are essential. - Textile Manufacturing

Fabric Handling: Assists in the handling and transport of fabrics and fibers. - Glass and Ceramics Manufacturing

High-Temperature Operations: Withstands high temperatures, ideal for the transport of delicate glass and ceramic items. - Chemical Industry

Chemical Resistance: Offers reliable transport solutions in environments with chemical exposure. - Logistics and Distribution

Sorting and Movement: Enhances operational productivity in sorting and moving goods in logistics and distribution centers.